Corporate

Marchesini Group will take part in the 23rd edition of Pharmtech & Ingredients, the International exhibition of equipment, raw materials and technologies for the pharmaceutical and cosmetic industries, that is taking place in Crocus Expo IEC of Moscow from 23rd to 26th November.

The Group will show its innovations in the field of digitization and will exhibit two machines (Pavillon 2.8 - stand A4047): a high-speed cartoner and a vacuum turboemulsifier suitable for processing liquid and creamy products for laboratories.

For this event, the Group will rely on the support of its Russian branch Marchesini Group RUS, which over the past 30 years have been providing personalised service and highly specialised assistance. This conjunction aims at not only strengthening existing partnerships, but also meeting the growing local demand for innovative technical and digital solutions.

In order to comply to these needs, Marchesini Group in cooperation with Sea Vision – a partner specialized in vision systems – will participate in the 16th International Pharmtechprom forum 2021 as part of Pharmtech & Ingredients, presenting a new tool in order to help pharmaceutical industries to improve the management of documentation and the control of production, in relation to GMP rules.

The conference entitled “Paperless manufacturing, EBR - Electronic Batch Record - for the pharmaceutical industry” will take place on 25th November from 15.45 to 16.15 during session D of the forum, dedicated to “Auxiliary processes in pharmaceutical production” (Hall 8, Pavillon2).

This presence further confirms the increasing importance of the Russian market in the Group strategies, especially this year in which Marchesini Group provided to pharmaceutical Russian companies the solutions for packaging of COVID-19 vaccines.

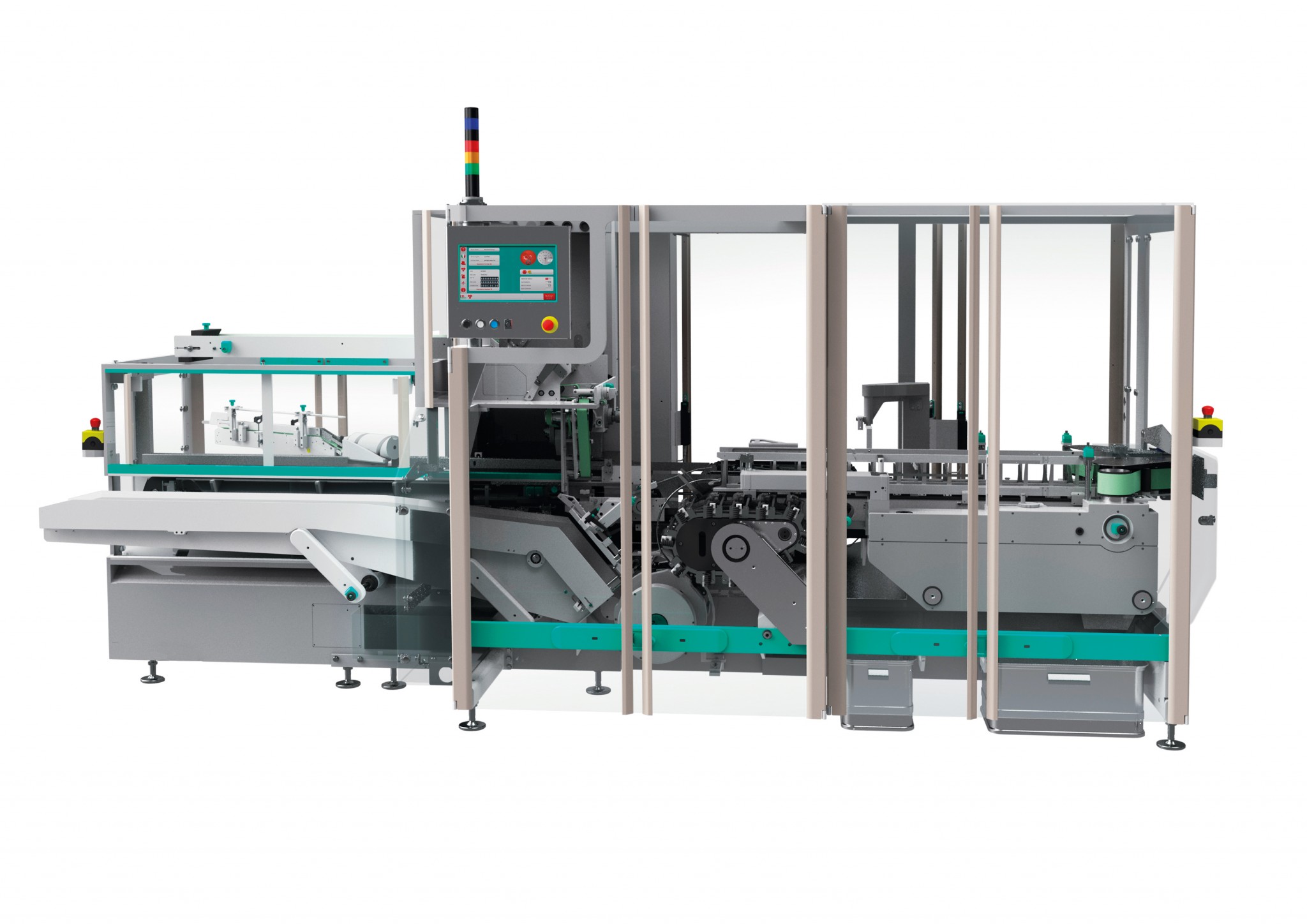

Marchesini Group will show in Russian exhibition a machine for secondary packaging, flagship of the company: MA 400. It is a continuous motion horizontal cartoner, completely restyled few years ago with improved ergonomics and user-friendliness.

This machine inherits the best of BA 400 cartoner, which since the 80’s has travelled the world, winning the appreciation of the pharmaceutical, cosmetic and food industries.

The MA 400 is compact in size - without compromising the machine’s high-speed output - and easy to use, thanks to a wide range of control functions that guarantee maximum efficiency and a new operator interface called “Easy Door”.

This version has several improvements from both a functional and aesthetic point of view: the new software makes the operating system more powerful and faster; the wider screen instead is more ergonomic and much more sensitive, similar to that of a mobile phone. The machine is a perfect solution for high-speed packing of all product types for the pharmaceutical and cosmetic markets: in particular the model on display, was designed for the packaging of products in vials.

The machine features a vision system produced by SEA Vision, composed of cameras and software performing the control of code on carton and leaflet. This system is able to control the 100% of the unit passing under cameras: depending on the results of the reading, the system indicates if the unit is good or must be rejected, thus assuring that the production on the MA 400 is perfectly compliant with the standards required in the pharmaceutical industry.

The other machine on display is the TURBO-MEK 10: a vacuum turboemulsifier suitable for processing liquid and creamy products for laboratories and very small-scale productions. This solution, which has a useful capacity of 10 litres, is produced by Dumek, the Marchesini Group company specialised in the design and manufacture of machinery for processing cosmetic and pharmaceutical products, with 40 years’ experience under its belt and over 4.000 machines installed worldwide.