Corporate

Contenuto disponibile solo in lingua inglese

Skyepharma’s development and manufacturing is eminently specialized in Complex Oral Solid Dosage Forms, through many years of involvement and achievements in the pharmaceutical industry.

Skyepharma’s State-of-the Art CDMO facility close to Lyon (France) provides solutions which bring value to clients at all stages of a product development lifecycle, from small-scale programs to commercial manufacturing and packaging activities.

Skyepharma’s value proposal includes services tailored to clients’ requirements supporting them up to market introduction. Skyepharma is part of the Vectura Group of Companies, an industry-leading device and formulation company specialized in airways disease.

Skyepharma chose the Marchesini Group and the Marchesini partner SEA Vision to answer its serialisation and aggregation needs.

The first line sold to Skyepharma serializes and aggregates 10 million boxes of pill bottles per year. A second line will be delivered in the coming months; it will be responsible for packaging, serializing and aggregating boxes of tablets in blister pack and it will handle 40 to 50 million boxes for blister tablets.

Intended for the American market, these packaging lines receives a datamatrix, a 2D marking allowing the product to be identified individually, in accordance with the serialization standards applicable since November 27th, 2017 in the United States.

The bottling line sold to Skyepharma is made up of the following machines:

Compact-12 Valida, with feeder Sirio 3 “Code”, is a monobloc counting and capping unit. The strong points of Compact 12 are its compactness, thanks to the fact that everything is carried out on just one machine, and simplification of the cleaning operations, as well as the possibility to accommodate operator protection (RABS) and product protection (Laminar flow) systems.

Compact-12 Valida has an electronic 12-channel counter and a capping unit to produce up to 60 bottles of tablets, coated tablets and capsules per minute. It accommodates all the main capping systems (screw-on, press-on, crimped) and also a wide choice of product control systems (100% tare/gross weight, shape, colour and size control).

The labeller model RE 202 is a fully automatic rotary machine developed by Neri, branch of the Marchesini Group specialising in producing this type of equipment.

Thanks to the finest of “Made in Italy” engineering, these machines are a benchmark for whoever needs not only a reliable labeller for pharmaceutical vials and ampoules but also a machine for tracking and serialising them.

The RE 202 is a technically advanced and user-friendly machine and offers customers extraordinary advantages, among which are ergonomics and straightforward management, thanks to its compact footprint and perfectly visible work area; efficiency in very quick size change-over operations; high level of precision in applying the labels; flexibility, which enables the installation of different tracking and serialization systems; last but not least, versatility in processing not only bottles made of a variety of materials (glass, plastic and metal), but also of different shapes (cylindrical, truncated cone, oval) and also with shaped profile and unconventional shapes, which is typical of the top-of-the-range cosmetic industry.

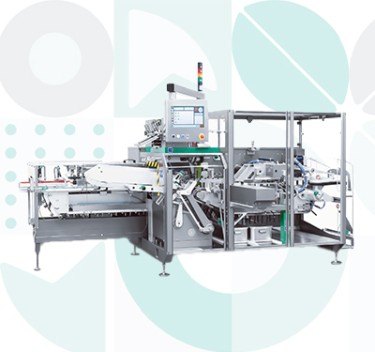

MA 100 is an intermittent-motion horizontal cartoner, entirely made with balcony construction, designed around three concepts: versatility, ergonomics and maximum efficiency in a small footprint.

BL-A415 is an automatic labeller for the application of one vignette on the upper panel of the carton or, as alternative, of two self-adhesive Tamper Evident seals on the closure points.

It is one of the models belonging to the large BL-A family: machines for labelling and tracking cartons, whose features of versatility and reliability are their key strongpoints

BL-A415 has been created to fully exploit its outstanding ergonomics: thanks to the work area that is separated from the mechanical and electrical parts, management and maintenance operations are very simple. All these top features make the BL-A415 a truly high-tech yet very user-friendly machine.

Bestpocket features excellent features including hygiene, compactness and transparency, offering operators a view of the whole production flow. It is able to aggregate thanks to SEA Vision systems.