Corporate

From October 17th to 20th, the Marchesini Group will be at the 19th edition of AllPack Indonesia, the dedicated B2B platform for Food & Beverage, Pharmaceutical Processing & Packaging Technology. Booth C3-C006 will host customers with the company’s renowned hospitality to illustrate the best of Italian technology for the pharmaceutical packaging industry.

The machine on show will be one of the Group’s great classics, the BL A420 labeller, one of the models of the large BL A family: machines for labelling and tracking cartons, whose features of versatility and reliability are their key strongpoints.

The BL A420 unit showcased at AllPack Indonesia has been created to fully exploit its outstanding ergonomics: thanks to the work area that is separate from the mechanical and electrical parts and to the very simple management and maintenance operations. All these top features make the BL A420 a truly high-tech yet very user-friendly machine.

The cartons are fed and accumulated in-line on the inlet belt to ensure a continuous flow of products, even at high speeds. A patented “timing” device positions and sets the cartons apart correctly on the toothed belts with adjustable opening, which also prevent slipping.

The function of the timing device is to set the cartons at the correct distance apart; its special feature is that it is synchronised with the speed of the whole conveyance system and there is no need for any size change-over adjustments.

The first operation to be performed after the cartons have been positioned is that of applying the optical seal or vignette on the upper panel of the cartons; then, the unique 2D code (Datamatrix) and the corresponding human readable data are printed on the side flaps and sometimes on the upper panel. The unique code identifies and makes it possible to track each carton.

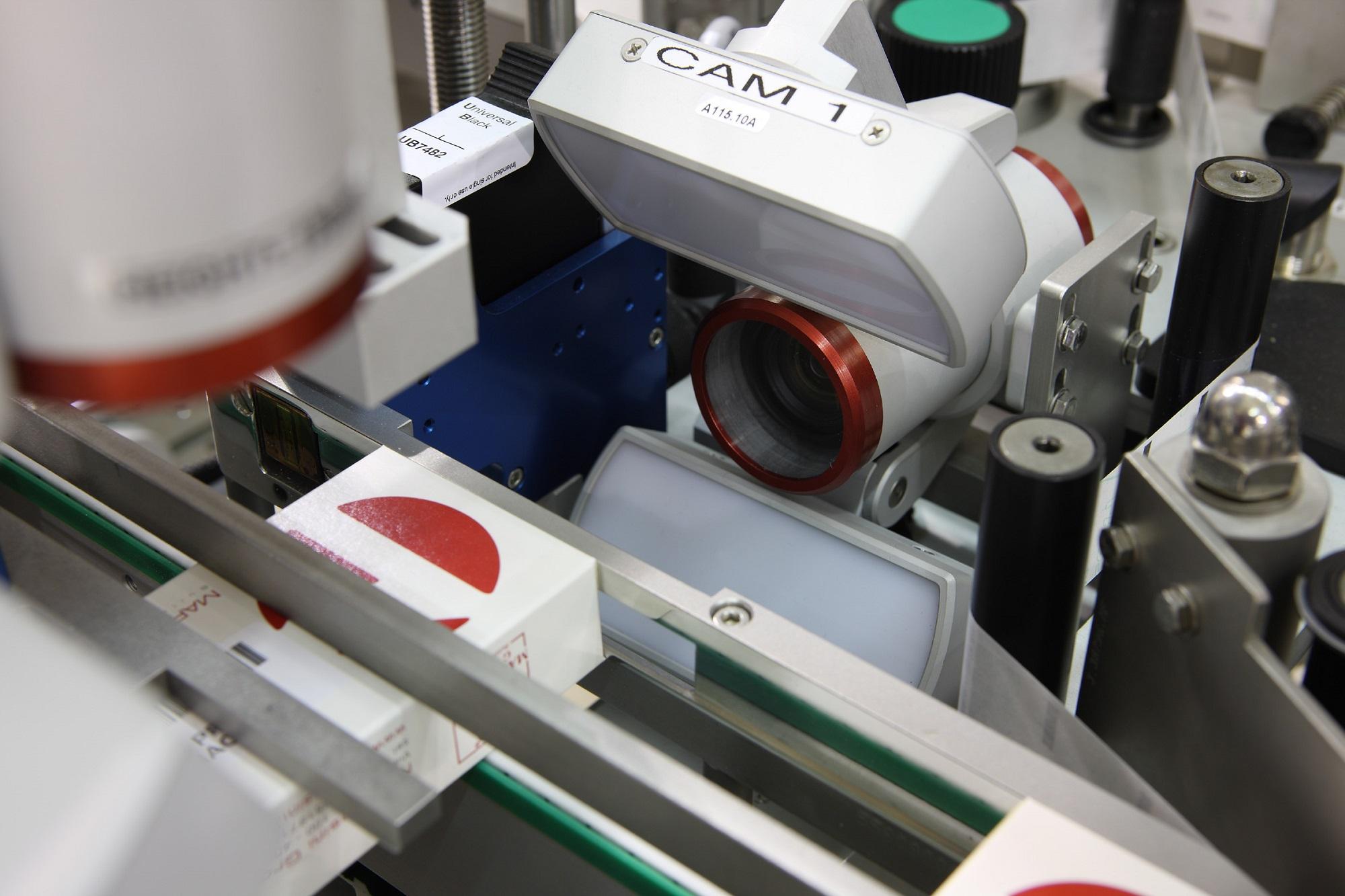

A camera then verifies both the codes and the readable data. Once the code has been completed in this way, two self-adhesive Tamper Evident seals are then applied on the corner closing points of the cartons.

All the label dispensing units are driven by servomotors, whose speeds are synchronised automatically with those of the carton conveyance system.

During these phases, the use of the “Fail Safe” operating logic means that only “correct” cartons are sent to the machine downstream, while the others are identified and rejected.

The BL A420 is incredibly flexible and can accommodate all the printing and vision systems available on the market, plus it can be personalised according to the various regulations in force around the world. This peculiarity makes the BL A420 the most suitable and complete machine for tracking, serializing and labelling cartons, so that all the pharmaceutical products packaged have a unique identity.