Corporate

The Marchesini Group will be presenting a monobloc unit at Pack Expo Las Vegas (September 23-25) that fills and caps bottles for pills, tablets or capsules. The Compact 12 showcased is one of Marchesini’s top-of-the-range solutions in the field of electronic counters and is equipped with special applications to guarantee total product control. One of these is the impressive HarleNIR vision system, which exploits a Near Infrared hyperspectral camera to chemically distinguish the pharmaceutical products by analysing their active ingredient. It was presented in April this year during the Open Factory dedicated to Industry 4.0 and Marchesini is the first company in the world to implement this technology to package blisters. Now, the HarleNIR system will be previewed onboard a counting machine for the American market.

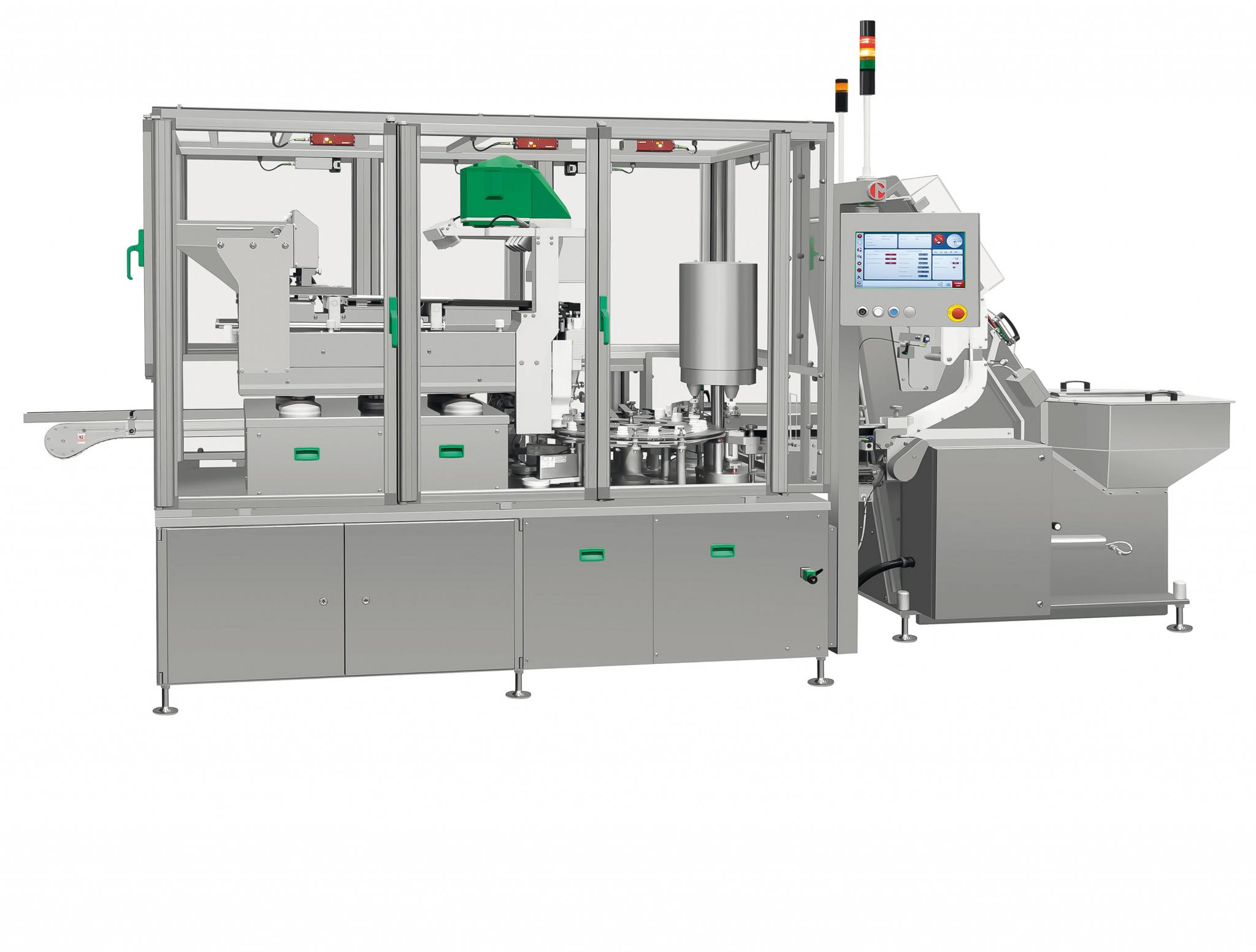

Compact 12 is a compact monobloc unit that integrates a variety of operations on just one machine and that guarantees very high levels of efficiency in the crucial counting and capping phases. Depending on the type of production and specific customer requirements, the machine can accommodate operator protection (RABS) or product protection (Laminar Flow) systems.

The machine is set up to handle all the main types of capping systems (screw-on, press-on, crimped) and offers the widest possible array of applications to guarantee total product control.

The various types of control systems can be activated together or partially, depending on the market, on the product to be packaged and on the requirements of the end customer. In particular, the following controls are featured:

By verifying the “exactness” of the active ingredient, this spectral analytic function provides important indications in the case of mixed-up ingredients, which is one of the main causes for a pharmaceutical to be withdrawn or blocked.

In this case, the HarleNIR system points out the error and the channel where it has been found and the machine is stopped. The same technology can be used for different solid oral products such as pills and capsules.

In such times of increasingly stringent standards, regulations and quality control requisites, hyperspectral imaging greatly improves inspection methods and provides pharmaceutical manufacturers with utmost security while offering them a brand new tool for their packaging lines.