Corporate

Paris-based Sanofi-Aventis S.p.A. installed a new stick-pack line in Q1 of 2019 in its Origgio, Italy, facility just outside of Milan. Both Maalox antacids and Doliprane analgesics are produced on the new line.

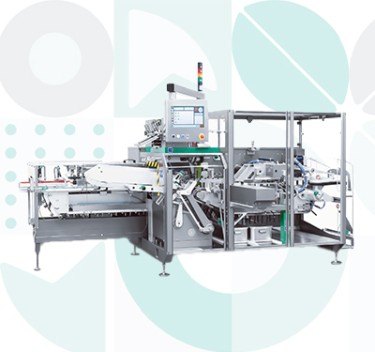

Essentially a turnkey line from Marchesini, the new line is capable of 800 stick packs/min. That’s twice the capacity of the stick pack line occupying the plant since 2008. This higher throughput is possible because not one but two Marchesini MSP 560L filling machines sit at the head of the line. Each takes a 600-mm-wide roll-fed lamination of polyester/foil/polyethylene, forms it into tubes 10-across, fills the required amount of liquid, and seals stick packs in any one of four sizes: 4.3, 10-, 8.3-, or 12.5-mL. Shelf life on the finished pack is two to three years, depending on which product and, to some extent, which region of the world it goes to.

Featuring a small footprint relative to comparable systems, the MSP 560L also has a greatly streamlined and software-based Clean-In-Place function that saves a lot of time when Sanofi switches from one liquid product to another. It also has a roll-fed film infeed system that has been simplified, says Marchesini, so that the operator can change the roll quickly and easily. The front of the machine allows easy access to the working parts, which means the operator has a clear and direct view of the entire packaging process. An automatic roll-centering device guarantees that the material is always correctly aligned with machine operations. As for date coding, each MSP 560 has two Videojet 3340 laser coders that mark all 10 lanes of packaging material. Paired with the laser coders is a vision inspection system from SEA Vision that verifies accuracy and legibility of the printed data.

According to Luca Angelini, Technical Services and Information Systems Manager at the Sanofi plant, his firm’s long-standing relationship with Marchesini made them an obvious choice when it came time to pick a machine supplier. But what really sealed the deal was their ability to design a dual-filler line. Each filler - producing stickpacks 10-across, or 10 per cycle - is capable of 400 three-side-sealed stick packs/min, so the combined output is 800/min. Should one filler be in need of service or maintenance, the other one is perfectly happy to operate alone. But if both are running simultaneously, which is usually the case, it means the downstream packaging systems had better be optimally efficient in their collating, cartoning, date coding, case packing, and palletizing functions. And both are they.

Perhaps most notable where secondary packaging is concerned is the use of intermittent-motion shuttles - one dedicated to each stick pack machine - and robotic pick-and-place units that smoothly transfer the stickpacks from the two machines that make them and send them into a 90-deg turn leading into the cartoning machine downstream. Mounted on a long elliptical shaped track, each shuttle holds 20 slots. The shuttle pauses beneath an MSP 560L so that 10 stick packs can drop into the front 10 slots. The shuttle then advances a short distance to the second MSP 560L machine so that 10 more stick packs can drop into the trailing 10 slots. Once all 20 slots contain a stick pack, the shuttle advances a short distance and pauses beneath a robotic pick-and-place unit that uses vacuum pickup cups to pick all 20 stick packs from their slots. The robot strokes forward while its end effector pivots 90 deg and drops all 20 stick packs into a continuous-motion flighted takeaway conveyor. In this way, the stick packs execute the 90-deg turn that takes them into the cartoning, case packing, and palletizing equipment downstream. As for the track-mounted shuttle, as soon as it has delivered its load of 20 stick packs to the robotic pick-and-place unit, it proceeds along the bottom half of its elliptical track until it arrives back at the two MSP 560L machines to receive another 20 stick packs.

Running parallel to the flighted takeaway conveyor on which the stick packs are placed by the robotic transfer is a bucket conveyor that is the infeed mechanism of the cartoner. A second Marchesini robotic pick and place unit, a Robocombi 380, uses vacuum pickup cups to pick 20 stickpacks at a time and place one in each bucket of this parallel conveyor.

Next in line is the MA 80G intermittent-motion cartoner. When the bucket infeed conveyor reaches this cartoner, stick packs are pushed into erected cartons, a leaflet is automatically inserted on top of the stick packs by a system from GUK, flaps are closed, and hot melt glue is applied by a system from Nordson. Integrated into the cartoner is a SEA Vision vision system that relies on a Cognex camera to check that the correct leaflet is being inserted into the right carton.

Quite impressive is the variety of secondary packaging formats Sanofi can produce on the line. “We worked closely with Marchesini to optimize changeover efficiency and to make it possible for operators, and not specialized technicians, to do changeovers,” says Angelini. “That is definitely a significant feature of the line. On the cartoner, for example, many of the parameters that need to be changed are pulled up automatically at a touch screen. Some adjustments are by hand, but not many.” He adds that he’s pleased that the number of operators required on the line is just two.

Three different products are filled on the line: Maalox, Maaloxan, and Doliprane. All stick packs are 25 mm wide. The 4.3-mL Maalox is 90 mm long, the 10-mL Maaloxan is 123 mm long, the 8.3-mL Doliprane is 130 mm long, and the 12.5-mL Doliprane is 140 mm long. Cartons hold 6, 10, 20, or 50 units.

A short distance from the cartoner is a Prisma checkweigher that makes sure each carton holds the correct number of stick packs. Next in line is a Neri BL-A420 pressure-sensitive labeler with an integrated Wolke M600 Advanced digital thermal ink-jet printer that prints a 2D Datamatrix code as well as variable data such as GTIN, serial number, batch number, manufacturing date, and expiration date. The Neri labeler also applies the “bollino,” a label for serialization required by the Italian Health Ministry, if the carton is destined for a market where the bollino is required. Also integrated into the Neri labeler is an Antares vision system that relies on two Cognex cameras to check that the correct variable data is being printed on the cartons and the correct bollino is applied.

A PS510 top-load case packer from Marchesini is next in line, and then an Etipack thermal-transfer print-and-apply labeler equipped with a pneumatic applicator prints variable data on a pressure-sensitive label and blows the label onto the case. Printed on this label is the following data: the producer, product code, product name, SCC number, batch number, manufacturing date, expiration date, case number, and tracking bar codes. Integrated in the case packer is a Datalogic scanner to control all tracking bar codes.

The final piece of equipment in the line is a Marchesini Ministratus palletizer. It uses a vacuum pickup head to pick one case at a time and place it on the pallet according to a predetermined pattern.

Angelini says that while the 800/min throughput is perhaps the most significant feature of the new line, he is also very pleased by how gently the stick packs are handled and by the way the stick packs are always under control. Coming out of the filling machines it’s always one stick pack per slot on the shuttle. Then it’s one stick pack per flight on the takeaway conveyor, after which the stick packs are transferred into the buckets of the cartoner infeed conveyor. “Every step along the way we have complete control of the position of the package,” says Angelini. “This is something new for us.”

*Author: Pat Reynolds, VP Editor Emeritus at Packaging World magazine