Corporate

Business development stories also contain some sentimental episodes. And the partnerships between customers and suppliers grow not only when supply and demand line up perfectly, but also thanks to recognition of common values. A good example of such a success is the partnership between Marchesini Group, a leader in the design and construction of packaging lines and machinery for the pharmaceuticals and cosmetics sector, and Sveba, one of the main European contractors (CDMOs) operating in the food supplements sector. Founded by pharmacist Vincenzo Salamone in 1994 in a small basement in the province of Como, Sveba has grown from a phytotherapeutic production lab into an industrial designer, developer and manufacturer of food supplements in various pharmaceutical formats. From its first plant in Cassina Rizzardi, Lombardy, the company expanded into the Basilicata region in Galdo di Lauria, where the Marchesini Group machines were delivered. For Sveba, this development was marked by the desire of the Salamone family, whose roots lie in Castelluccio Superiore, Basilicata, to return to their origins.

To strengthen its bonds with the local area, a value which has also always driven Marchesini Group, Sveba chose to put its trust in the innovative packaging technologies from the multinational based in Pianoro, near Bologna, in order to drive production growth with significant benefits in terms of employment too – in 2025 the company plans to inaugurate a further production plant in Castelluccio, with the construction of a new plant of over 5,000 square metres in Galdo di Lauria to take place in the next three years.

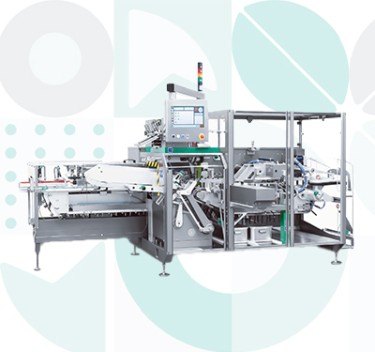

After an initial visit to Galdo di Lauria itself, the partnership was immediately confirmed: the solutions proposed by Marchesini Group were identified as being the best to meet Sveba’s requirements. The first project to be set in motion was with the INTEGRA 220: the customer was able to observe the different lines undergoing testing at the factory in Pianoro. Interest then extended to a COMPACT 12 for filling bottles with tablets, and a MT 1300 + MA 80 powder stickpack line.

The INTEGRA 220 is the monobloc blister and cartoning machine for production of both capsules and tablets. It was built in record time to meet Sveba’s requirements. Compact and flexible, it easily adapts to different production requirements. The blister packaging machine, with size changes of just 20 minutes, allows production times to be optimised, increasing operational efficiency: this is very useful when faced with small lots and frequent product changes, typical conditions for supplement manufacturers. It can work with both traditional plastics and environmentally sustainable mono-material solutions. The cartoning machine stands out for its robustness and ease of use. The supplied model can operate in standalone mode, a very useful function for completion of batches or for packaging blisters already previously produced.

The COMPACT 12 recently installed in the Galdo di Lauria plant is an excellent solution for counting of food supplements or natural herb-based products. The lack of film application, and therefore the high level of dust involved in these products, makes their handling particularly problematic.

The COMPACT 12 is a counting and capping monobloc machine with a small footprint and excellent accessibility, able to produce up to 60 bottles per minute. It is equipped with an efficient dust capture unit, as well as a highly accurate counting system able to offset the progressive accumulation, always guaranteeing the necessary measurement precision for the products in transit. The ability to “contain” both the filling and sealing operation of the bottles within a closed structure also provides effective reductions in the amount of dust dispersed within the work area.

The stickpack packaging line built for Sveba is one of the Group’s most consolidated solutions, and is composed of the MT 1300 filling machine and the MA 80 cartoning machine.

The MT 1300 is an intermittent-motion automatic vertical machine, designed to package powdered food supplements in practical stickpacks. This solution is equipped with an auger dosing unit with independent drives, allowing for individual regulation to ensure a very low dosing tolerance and high accuracy up to production speeds of 500 sticks/min. Thanks to its versatility, this packaging system allows different doses to be managed with genuinely short size change times, while maintaining a high level of efficiency and accessibility. The stickpacks produced by the MT 1300 are deposited on a step conveyor belt feeding out the side of the machine to ensure facilitated inspection. Subsequently, the stickpacks are transported into an intermediate station where a robot, designed and built by Marchesini Group, sends them for secondary packaging.

“The purchase of the new lines will allow us to increase our production capacity without taking away the possibility to also manage smaller batches,” highlights Antonio Lista, Manager of Sveba. “Our choice of Marchesini Group to supply these new lines was dictated by the need to be able to manage not only the quantity, but also the quality of our production. Our partnership with Marchesini Group will also continue into the next three-year period with the construction of our new plant, which will require lines that offer even higher production capacity, innovation and advanced technology.”