Corporate

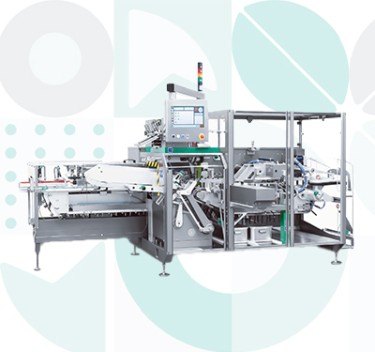

An extraordinary syringe and vial packaging line, able to guarantee the highest productivity without breaching the customer’s sustainability requirements. The latest result of the established partnership between Marchesini Group and PCI Pharma Services is a line that is truly out of the ordinary, in terms of both the number of individual machines it contains – ten, plus two robotic islands – and its conformation. In fact, the line, which is to go into operation at PCI Pharma Services European Center of Excellence of injectable packaging in Dublin, Ireland, has been designed to produce two different packs: a thermoformed plastic tray containing a syringe, two needles and a vial and a paper tray with ten syringes.

The two “lines within the line” are independent, allowing alternative operation of the process which packages the product in the plastic or cardboard packaging, depending on the customer’s production needs.

The line’s composition in three points:

The line’s real sustainability in two points:

Simone Albanese, Marchesini Group Area Manager: “This syringe line project is one of the biggest of the many which Marchesini Group and PCI have brought to completion. The in-depth analysis of the line’s specific features, the development of its technology and the choice of the most suitable solutions required a high level of collaboration between our two companies, made possible by the years of projects undertaken together. The result is a very high capacity line able to process a large quantity of products while maintaining excellent flexibility in terms of type of output. We are obviously delighted with this result.”

Paul Smallman - Senior Director Global Technical Sales, PCI Pharma Services:

“The requirement for a technical solution was by far the most complex for our European commercial packaging site to date, and Marchesini Group was able to solve and provide a turnkey solution utilising the network of divisions within their group.

Supporting our client partners commercial launch, the provide was time bound and even with several scope changes throughout including the late addition of the need to add an environmentally friendly 10 and 20 count paper tray format, the Marchesini Group was able to solve for these, and other scope changes without compromising cGMP product flow or operational efficiency. Having Marchini Group manage the full line build from concept to FAT with continued support though SAT to PV significantly assisted PCI with resource management, streamlining supply chain by not having to manage the complexity of multiple vendors & Integrators. Marchesini Group proved themselves once more to be a true valued partner to PCI.”

About PCI Pharma

PCI is your world leading CDMO, truly spanning the cycle, connecting development and commercialization, de-risking the supply chain providing clients with integrated end-to-end drug development, manufacturing and packaging capabilities that increase their products’ speed to market, and opportunities for commercial success.

PCI brings the proven experience that comes with more than 90 successful product launches each year and over five decades in the delivery of CDMO services. Leading technology and continued investment enable us to address global outsourcing development needs throughout the product lifecycle.

PCI offers a global network of innovative centers of excellence for the development, manufacturing, packaging, storage, and distribution of life changing therapies. Our specialist contained manufacturing and packaging facilities dedicated to processing highly potent drug products, combined with our renowned lyophilization and sterile manufacturing capabilities are complemented by a global network of packaging facilities delivering a true end-to-end service. Our aim is simple, to accelerate your product from development to commercialization as efficiently and cost-effectively as possible.