Corporate

The Marchesini Group sold three similar blister lines to OBL Pharm, a Russian pharmaceutical company specialised in the development, production and promotion of modern and high-quality pharmaceuticals.

OBL Pharm produces more than 150 prescription and over-the-counter pharmaceuticals for gastroenterological, cardiologic, phlebologic and neurologic diseases, as well as for the treatment of acute and chronic pain, insomnia, men’s health and more. The Company’s portfolio includes both innovative and generic pharmaceuticals.

Step 1: the blister machine

The automatic thermoformer MB 451 Evolution belongs to the Marchesini range of thermoformers. It is designed and built exploiting “Made in Italy” technologies at the Headquarters of Marchesini Group in Pianoro. The MB 451 Evolution has five main work sections.

1) The forming reel compartment is at the back of the machine in a handy position so that it can be easily loaded. It holds two reels to ensure long processing self-sufficiency. Rapid splicing of the forming film, automatic film stoppage and the absence of dust thanks to the compartment’s closure system help to create an efficient and well organised work zone.

---> READ MORE: The collaboration with OBL Pharm involves our strategic partner SEA Vision.

2) and 3) The material pre-heating and forming station is also situated at the back of the machine at an ergonomic height for loading, also keeping the operator and product away from feasible fumes. The plates open when the machine stops and can be replaced without having to use tools.

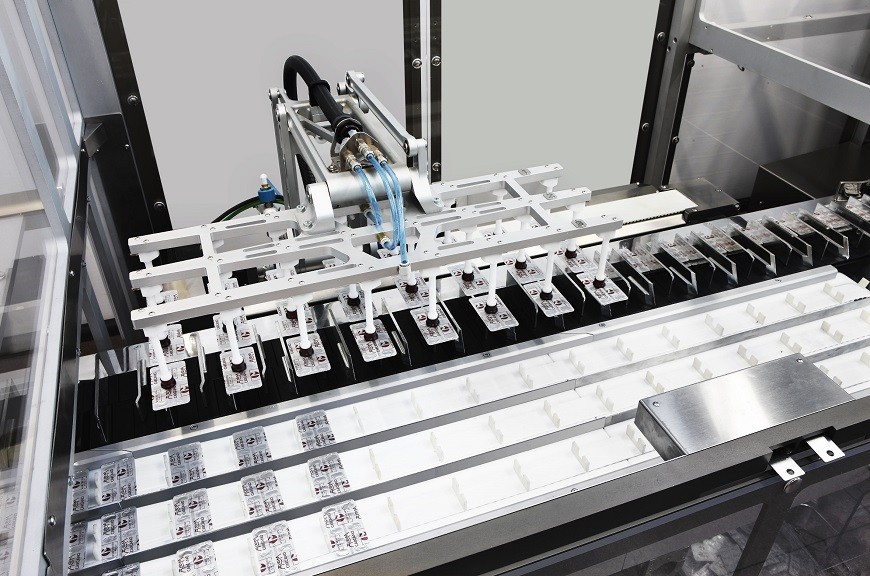

4) The pills or capsules are put into the infeed station where cameras check the presence of the product.

5) The station that seals the blister with the top film is on the flat and the carriage follows the movement of the film. After sealing, the blister is cooled by special plates before it is transferred to the perforation, coding and cutting station, built vertically so that it is self-cleaning from process waste.

Among the main accessories available to customers are special size change-over carriages, multiple product infeeds and additional cameras to check product presence.

The MB 451 Evolution is easy to install on a line in any workplace because it is very compact and flexible to connect to the machines downstream. In OBL Pharm’s case, the thermoformer is in-line with the MA 357 automatic Horizontal Cartoner and the FA 04 bundler.

Step 2: the cartoner

MA 357 is an automatic Horizontal Cartoner. This machine has three strongpoints:

Step 3: the bundler

The FA 04, at the end of the line, bundles the cartons containing the blisters. The machine has a balcony structure so that all the parts involved in the product flow are clearly visible, also to minimise maintenance work and to ensure simplicity of use.