Corporate

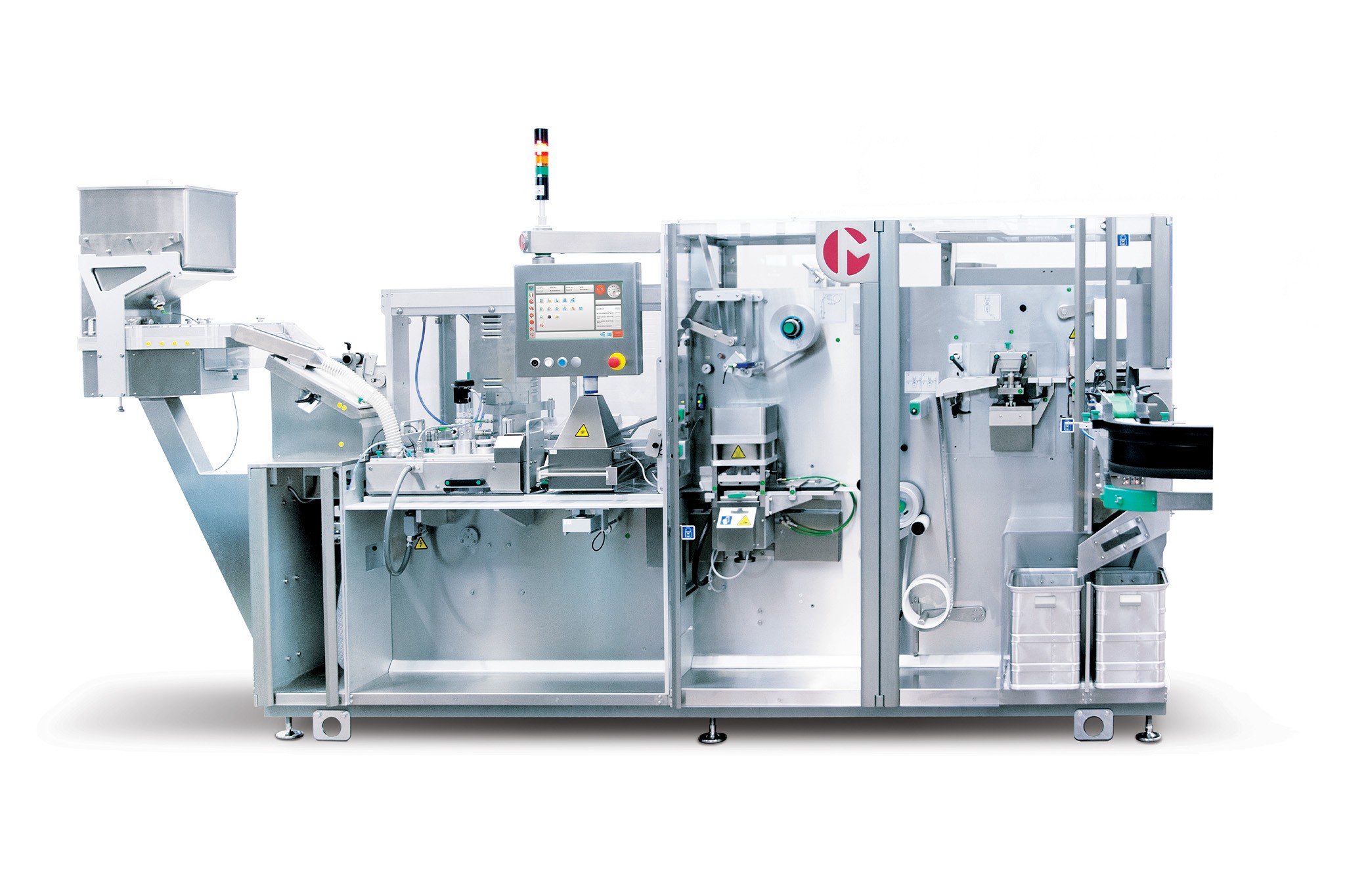

Cutting-Edge “stand alone” Machines.

Marchesini Group is able to offer a wide range of stand alone machines suitable to meet all customer needs, ensuring maximum reliability in terms of performance and production flexibility.

Main features:

Featured Model: MB422

| OUTPUT | |

|---|---|

| Production speed: | Up to 600 blister/min |

| BLISTER SIZE | |

| Width: | 30 - 86 mm |

| Height: | 3 - 12 mm |

| Lenght: | 70 - 140 mm |

Receive the machine brochure in pdf format, directly in your e-mail inbox.