Corporate

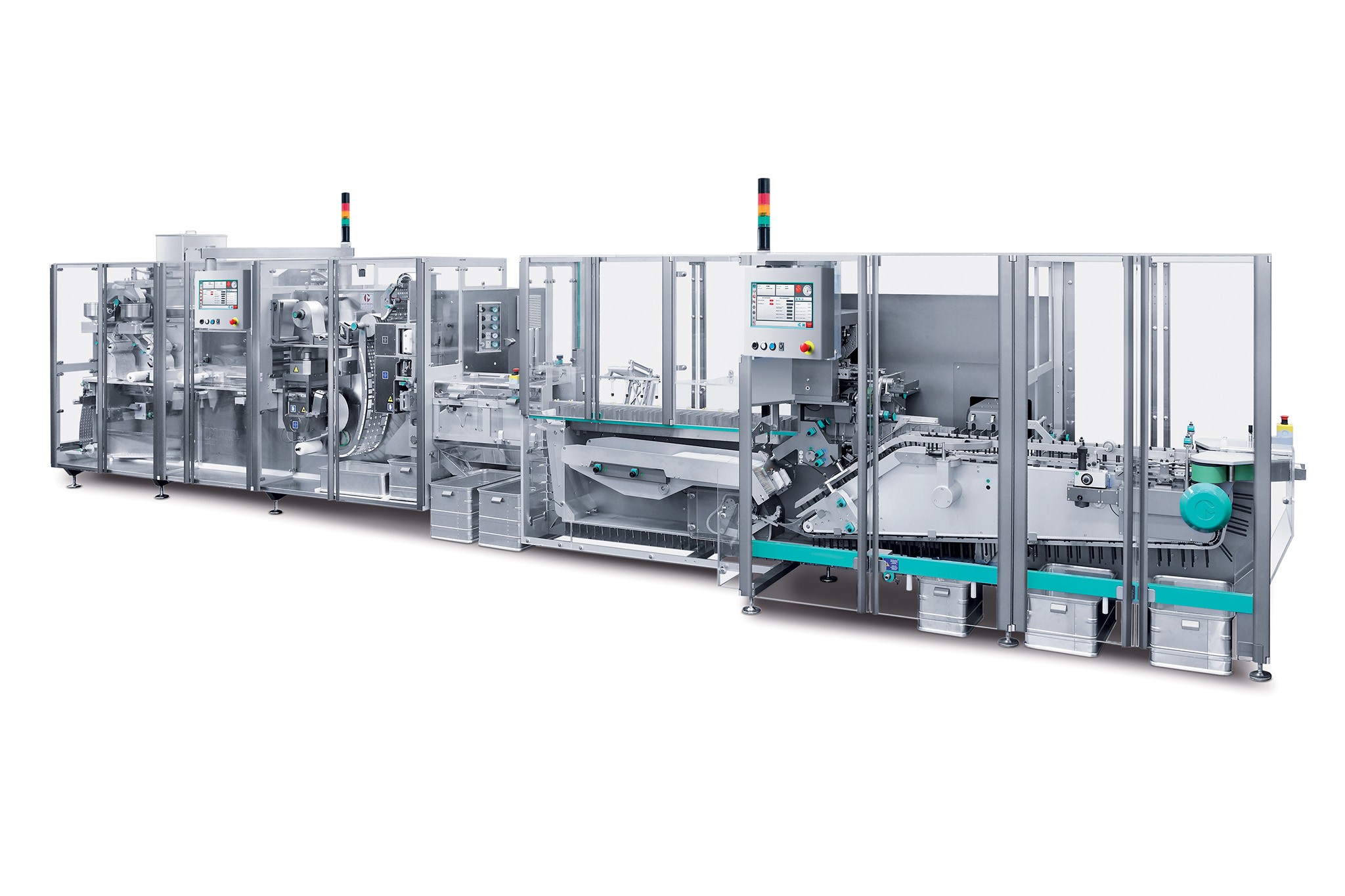

Integrated continuous motion monoblock machine.

The blistering section is managed by servo motors and features two splicing tables with hidden cutter and automatic grip vacuum. A rotating unit picks up the blisters from the die cutter and positive deposits it on the connecting conveyor. Thanks to a 3 axis translation, the ROBOCOMBI, a robotized blister feeding system, carries out different kinds of blister stackings on the bucket belt of the cartoning section.

Main features:

Blister section available as stand alone machine

| OUTPUT | |

|---|---|

| Speed: | Up to 320 blister/min |

| BLISTER SIZE | |

| Width: | 30 - 86 mm |

| Height: | 3 - 9 mm |

| Length: | 70 - 140 mm |

| CARTON SIZE | |

| Width: | 30 - 90 mm |

| Height: | 15 - 90 mm |

| Length: | 75 - 150 mm |

Receive the machine brochure in pdf format, directly in your e-mail inbox.