Corporate

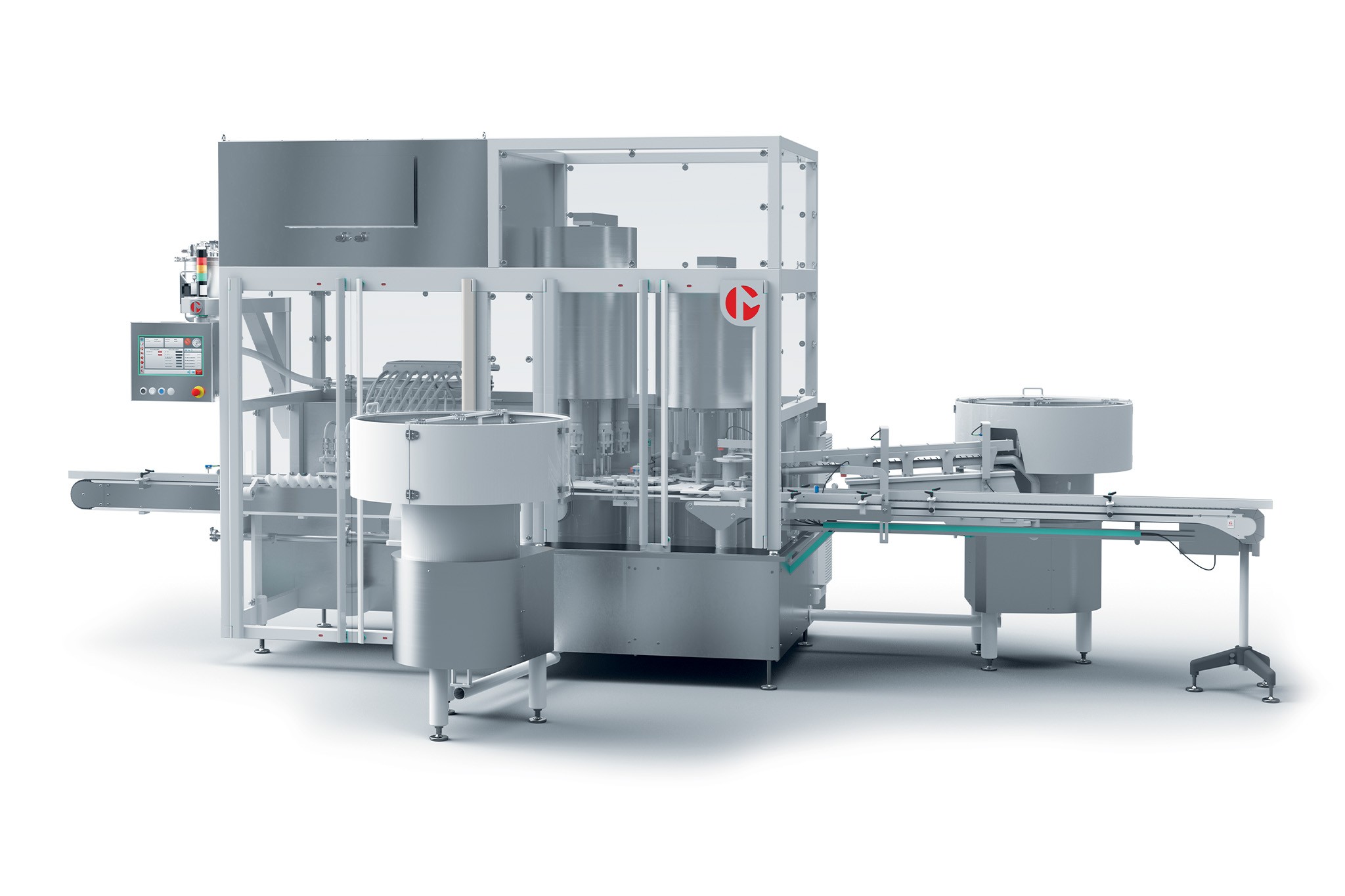

Monoblock linear filler with continuous rotary closures, available in different configurations.

Design with clear separation between the dosing-capping section and the drive mechanisms which are placed inside the machine basement. The machine filling area is with balcony design and bottles transport is made on the infeed conveyor.

Main Features:

| OUTPUT | |

|---|---|

| Speed: | Up to 200 bottles/min |

| PRODUCT RANGE | |

| Liquid Dosing Range (ml): | 0,5 - 500 Steel 0,5 - 300 Ceramic |

| Container diameter Ø: | 18 - 70 mm |

| Width x Width square container: | 20 - 70 mm |

| Long side rectangular container: | 20 - 70 mm |

| Short side rectangular container: | 20 - 60 mm |

| Container height: | 35 - 180 mm |

Receive the machine brochure in pdf format, directly in your e-mail inbox.