April 17, 2017

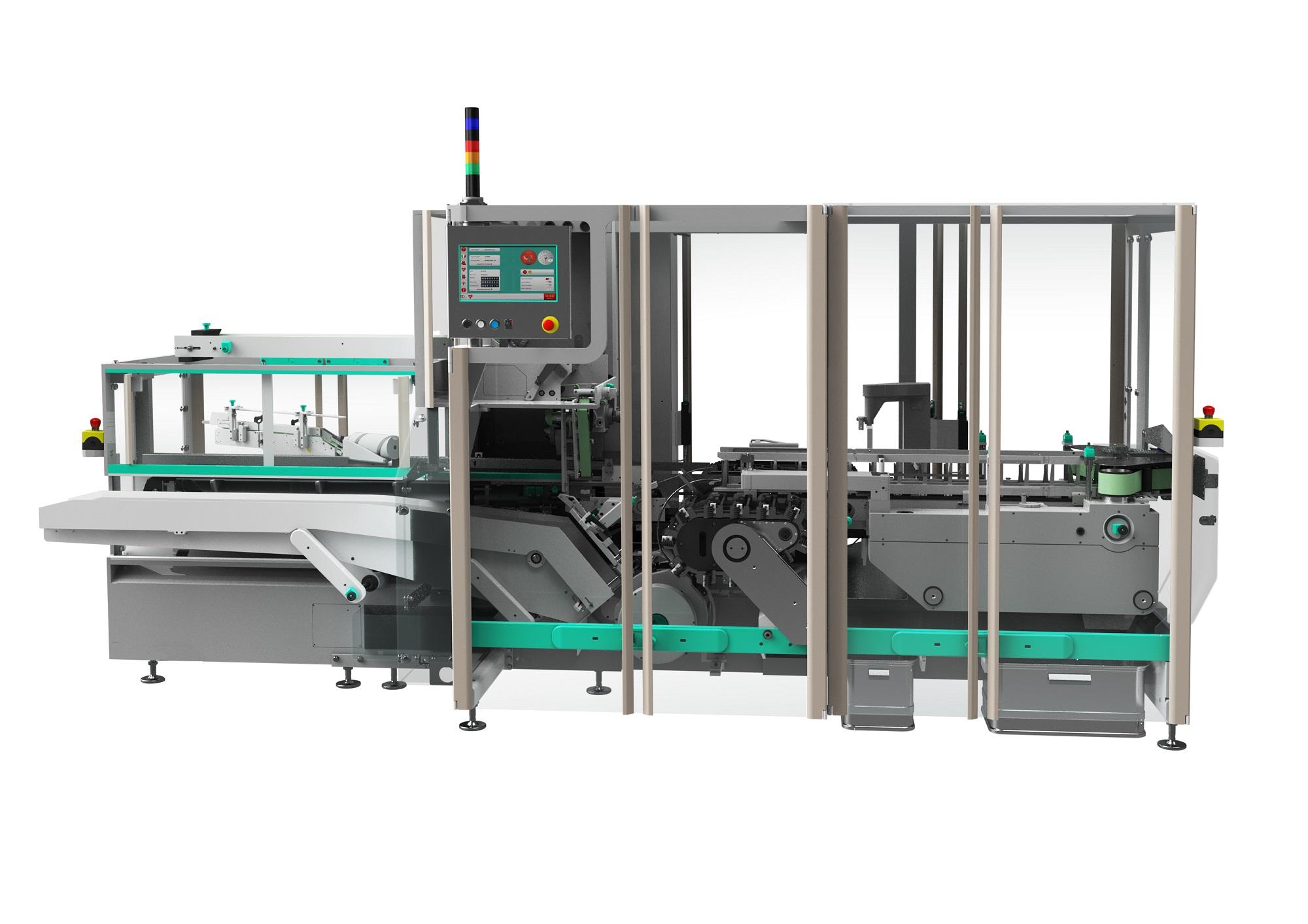

MA 400 CARTONER: A COMPLETELY RESTYLED MACHINE FOR HIGH-SPEED PACKAGING OF ALL PRODUCT TYPES

MA 400 continuous motion horizontal cartoner is a completely restyled machine with improved ergonomics, reliability and user-friendliness. This machine inherits the best of BA 400 cartoner, which since the 80’s has travelled the world, winning the appreciation of the pharmaceutical, cosmetic and food industries, thanks to its reliability and ergonomic design.

The MA 400 guarantees extremely fast changeover times and low maintenance. It is compact in size - without compromising the machine’s high speed output - and easy to use, thanks to a wide range of control functions that guarantee maximum efficiency and a new operator interface called “Easy Door”. This version has several improvements from both a functional and aesthetic point of view. The new software makes the operating system more powerful and faster. The wider screen is more ergonomic and much more sensitive, similar to that of a mobile phone.

The new machine is a perfect solution for high-speed packing of all product types (blisters, bottles and vials, rigid and squeezable tubes, sachets and trays) for the pharmaceutical and cosmetic markets.

Technical features

The technical features and the control and safety functions that make the MA 400 a reliable machine are the following:

- balcony style structure for easy access and cleaning;

- conforms to cGMP regulations;

- quick and easy size changeover from the machine front;

- component feeding units located in ergonomic positions for easy access;

- carton opening, product transport and insertion, and carton closing systems combine renowned mechanical features and advanced technology;

- main mechanical parts with oil bath reduce maintenance and noise levels;

- separate reject containers (for product, carton and leaflet) for quick and easy reject management;

- traditional and robotized feeding systems available for all product and component types;

- touchscreen PC manages all machine functions and diagnosis with help function to reset faults;

- complete range of printing and print verification systems available;

- emergency and safety circuits in line with “CAT3 Pld”;

- carton and leaflet pick-up only when product is present;

- triple check for product-carton-leaflet presence;

- minimum load sensors for product-carton-leaflet;

- checking device for correct carton opening;

- checking device to verify leaflet presence before insertion into carton;

- mechanical pusher safety device;

- mechanical overload control unit for the machine;

- safety guards with wide doors for easy access.