Corporate

In addition to the innovative a-eye lipstick system by SEA Vision, paired for the first time with a Cosmatic lipstick machine, Marchesini Group Beauty's stand at Cosmopack 2024 will showcase a wide selection of machines and lines for packaging cosmetic products. Among the novelties featured at booth A9PK - pavilion 19PK is also a line for packaging products in bottles, the result of close collaboration between two of the brands that make up the cosmetic division of the Group: Vibrotech and Axomatic.

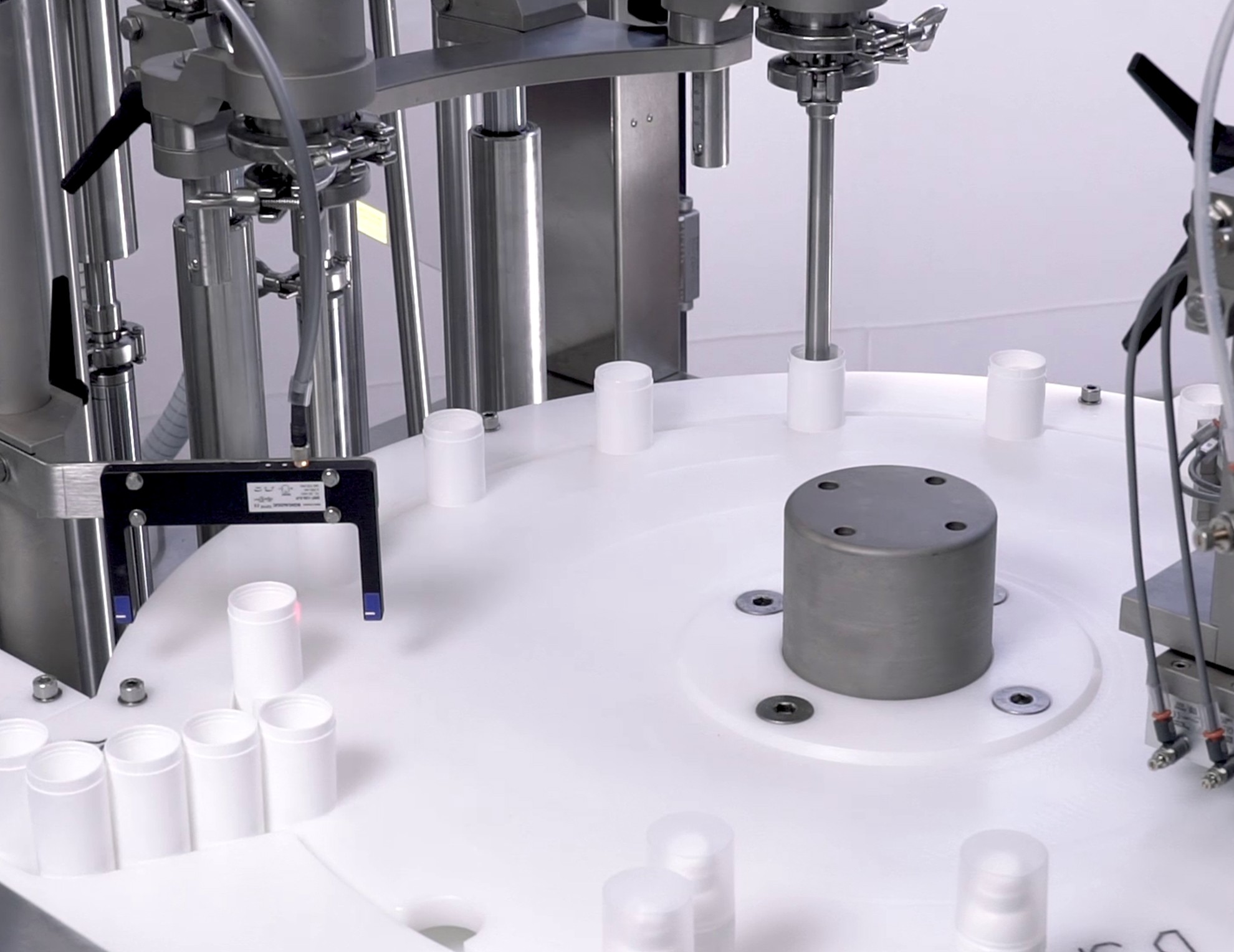

The synergy between the two brands has resulted in a line composed of a robotic feeding system, perfectly integrated with a linear filling and capping machine for stable bottles. The system, developed by Vibrotech, consists of a rotating selection disk, a belt (or vibration) hopper that doses the products onto the rotating disk, a vision system that detects the products to be picked, and finally a Scara robot that picks up the products and deposits them at an output speed ranging from 25 to 40 pieces per minute. The system, efficient and optimal for delicate product handling, has then been integrated with a simple and compact solution for dosing and capping various cosmetic products in stable bottles at a maximum speed of 40 pieces per minute.

The stainless-steel filler and capper, ergonomic and compact, are produced by Axomatic: in particular, the linear filler is equipped with four dosing units that ensure accurate dosing of liquid and dense products, and four descending nozzles that allow for perfect product deposition inside the bottles from bottom to top, controlling the descent and ascent speed of the nozzles themselves.

Among the solutions for the first time at Cosmopack is also a monoblock filler branded Rejves, which provides filling and capping of bottles: it is characterized by the use of dedicated load cells capable of ensuring accurate dosing, with precision up to 0.1%, which ranks among the best in the category. Also on display at the booth is a line for tubes, first filled and closed by an Axomatic tube filler, then placed in a box by the V2 engineering horizontal intermittent motion cartoner, and finally packaged by the automatic wrapper, also produced by the same brand. Finally, there will also be state-of-the-art turboemulsifiers from the brands Dumek and Axomatic with capacities ranging from ten to a thousand liters.