Corporate

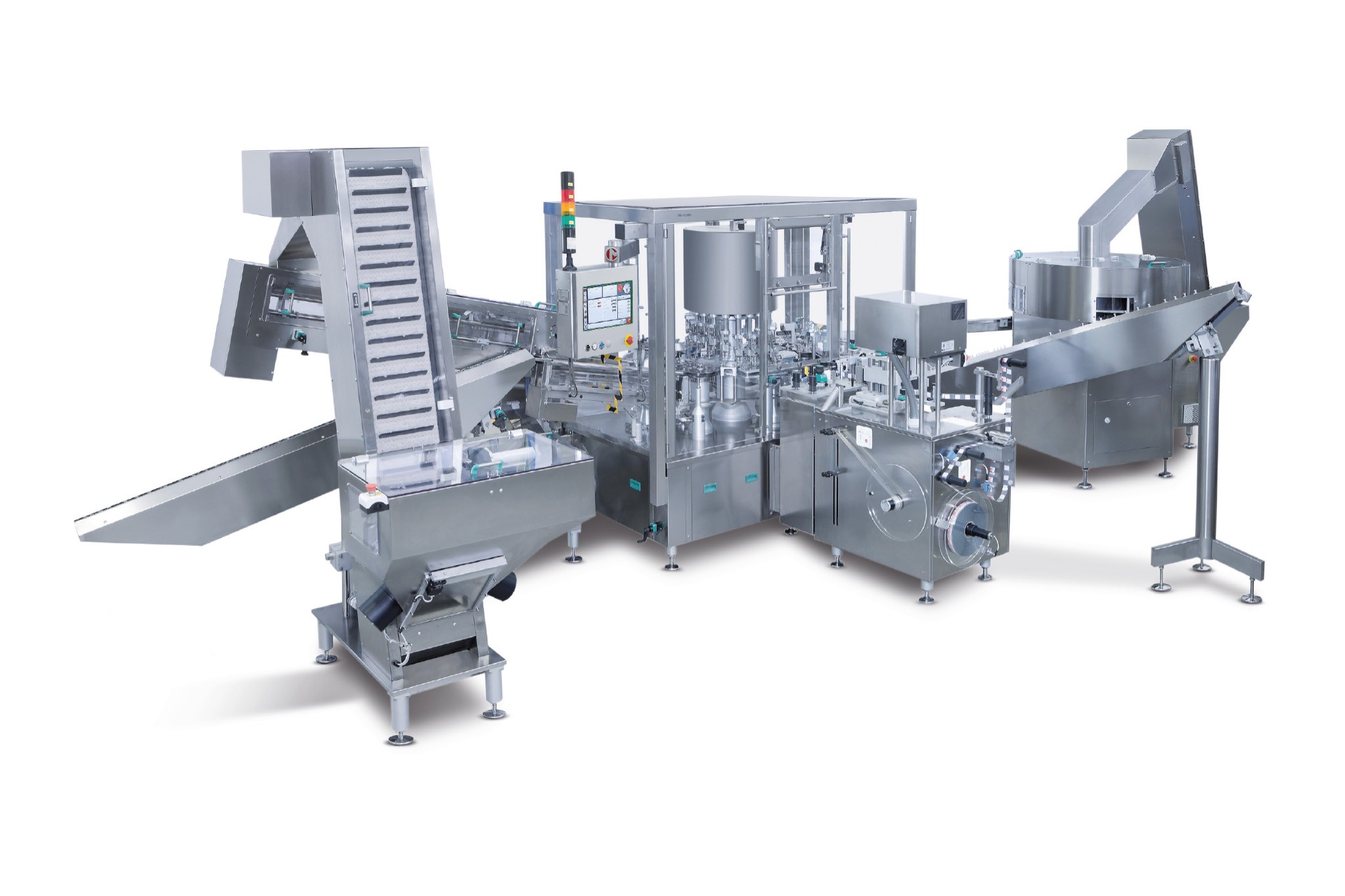

Macchina automatica a movimento continuo per l’astinatura, l’etichettatura e l’assemblaggio dei Backstop su siringhe di vetro o plastica.

Caratteristiche principali:

| OUTPUT | |

|---|---|

| Speed: | Up to 18.000 syringes / h with backstop Up to 24.000 syringes / h without backstop (by-pass mode) Up to 24.000 syringes / h for the COMBI-1BS model |

| PRODUCT RANGE | |

| Syringes: | from 0,5 to 20 ml |

Ricevi la brochure della macchina in formato pdf, direttamente nella tua casella di posta.