Corporate

Contenuto disponibile solo in lingua inglese

A well-known Italian company producing cosmetics, medical devices, food supplements and probiotic-based drugs has commissioned us a new line for filling pharmaceutical liquid products in stickpack and packaging in cartons.

For us, it was not a line like any other. Not only for the particular period in which it was delivered, during the second wave of Covid-19 in Italy, but above all for the extraordinary synergy of know-how between Marchesini Group and Schmucker, one of the latest companies to join the Group. Group integration that has undergone a process that we have called a "family feeling imprint": a series of technological developments that have resulted in the Schmucker solutions becoming even more ergonomic, easily accessible, quickly upgraded, retrofitted and expanded.

The new Stickpack MT1300 solution - in line with Marchesini Group’s MA80 cartoning machine - is the result of a new family of machines from Schmucker, a firm that has been leading the stickpack & sachet machinery sector for over 40 years. Having merged in 2018 with the Marchesini Group automation systems, Schmucker has reached the highest level of integration between primary and secondary packaging, and therefore offers advanced flexibility and overall line efficiency.

The MT1300 machine is an intermittent motion filler for packing tubular sachets sealed on three sides called “sticks”. This solution handles liquid products but MT family of machines can also handle creams, gels, pasty products, powder, granules, single pieces and so on, in the pharmaceutical, cosmetics and even F&B sectors. Thanks to cutting-edge technology, the filler output can reach up to 65 cycles/min, (depending on the product and stick specifications).

There are three main advantages in the Stickpack MT1300 solution:

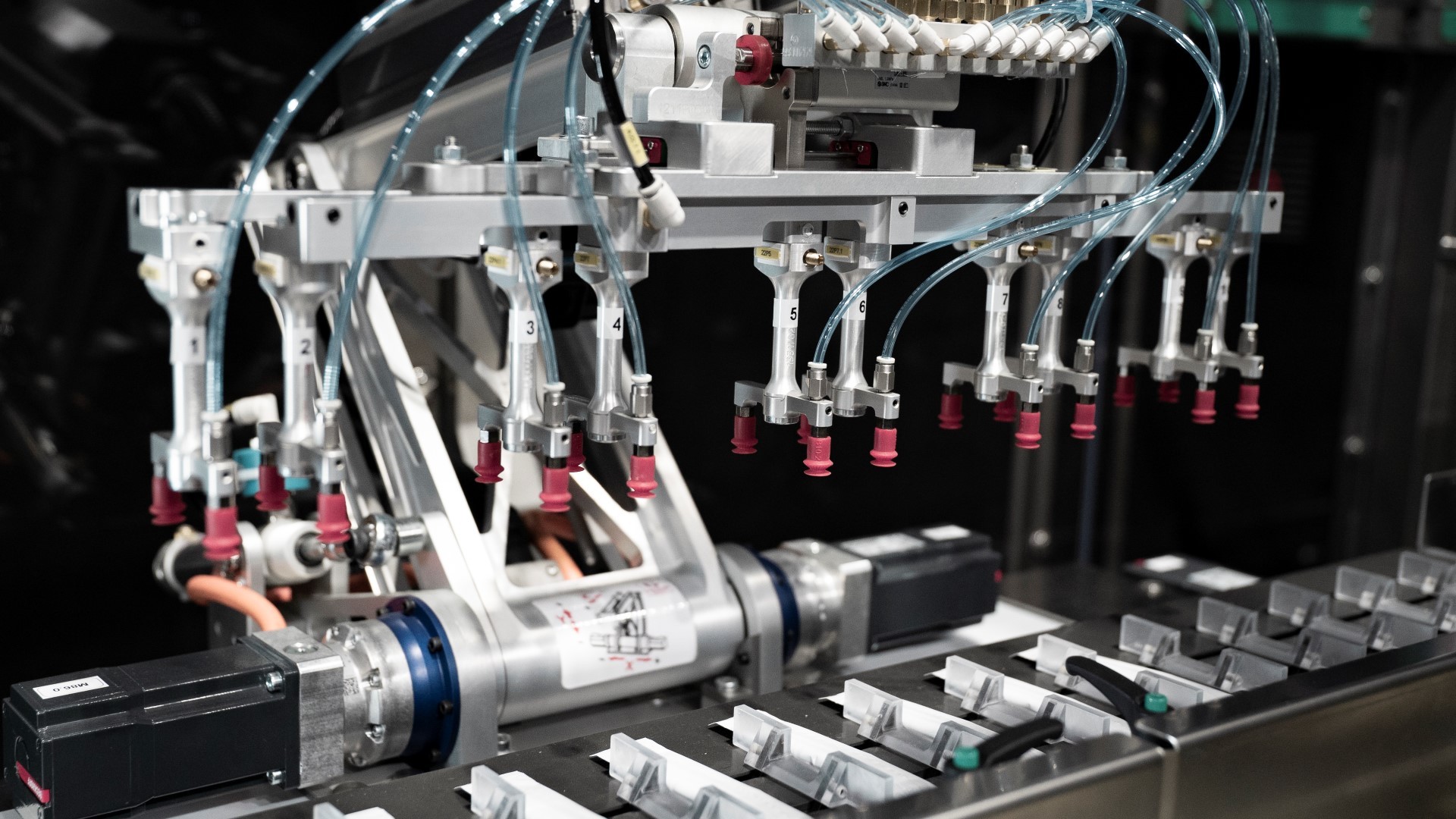

This multi-lane dosing unit uses the principle of vertical syringe/rotary valve (all in one part), ensuring high performance and accuracy. This particular configuration represents advanced technology combined with the ergonomics of the machine.

At the end of the line, the MA80 intermittent motion cartoner arranges the stickpacks neatly and orderly in the buckets and then in the carton, inserting a folded leaflet and finally closing the carton with hot glue.

This particular solution has an output of 50 sticks per minute per lane and 36 cartons per minute with 14 sticks per carton, but the MA80 model can generally reach a mechanical output up to 120 cartons/min.

Like all Marchesini Group machines, this cartoner is reliable and built to last and it is designed to ensure that size changes are user-friendly and fast.