Corporate

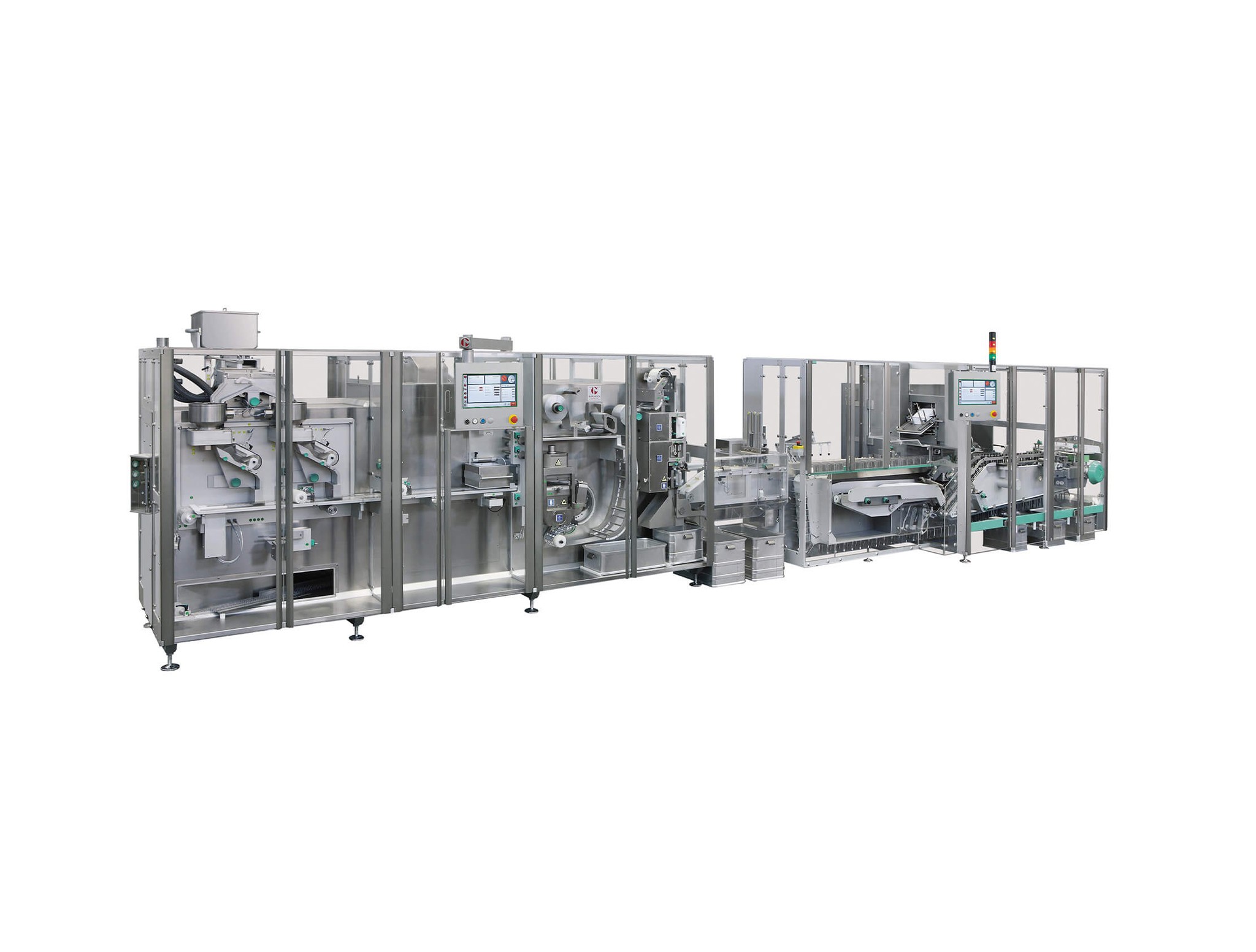

Integrated continuous motion monoblock machine. The blistering section is managed by servo motors and features two splicing tables with hidden cutter and automatic grip vacuum. A rotating unit picks up the blisters from the die cutter and positive deposits it on the connecting conveyor. Thanks to a 3 axis translation, the ROBOCOMBI, a robotized blister feeding system, carries out different kinds of blister stackings on the bucket belt of the cartoning section.

Main features:

| BLISTER SIZE | |

|---|---|

| Width: 30 - 86 mm Length: 70 - 140 mm Forming depth: Up to 9 mm |

|

| CARTON SIZE | |

| Width: 35 - 90 mm Height: 15 - 90 mm Length: 75 - 150 mm |

|

| OUTPUT | |

| Blisters/min: Up to 320 Cartons/min: Up to 260 with continuous motion |

Integrated product sorting unit

Dedicated “high-speed” product feeder

Sealing station, perforation station, mechanical embossing and cutting station

Positive downstream connection through Robocombi pick and place system

Continuous motion cartoner for blister secondary packaging with double set of pushers and counter-pushers

Receive the machine brochure in pdf format, directly in your e-mail inbox.