Corporate

Recently, during the most difficult times of the Covid-19 pandemic, we managed to deliver a new highly automated packaging line to GSK UK to handle three different auto-injection devices for key new products. Products include a new Biopharmaceutical product used to treat patients who suffer from severe eosinophilic asthma and another Biopharmaceutical Injection for treatment of Lupus.

When Marchesini won the tender from GSK UK to supply a complete line for packaging the three devices, at a speed of 140 per minute, we came up with a solution consisting of six machines and five Marchesini robots, capable of handling two different sizes: single device laid flat or four devices positioned next to each other.

The line has been designed for rapid size change and line clearance operations and just successfully completed all OQ Qualification activities with PQ planned in July 20.

Upstream from the GSK line there is a tray emptying unit to feed the trays with the devices. A Gigacombi followed by a Robocombi empty the devices from the trays and feed them onto the conveyor belt connected to the twin-head labeller RE 302 2T, which wraps a label around the device and applies a label on the front and back of it too. The RE 302 by Neri Division has a series of advantages for the customer: a smaller base, full access and visibility of the work area, quick size change-over operations thanks to special digital indicators and high label application precision. To conclude, it is highly versatile: RE 302 can handle products made from different materials, from glass to plastic, but also various shapes and sizes, be they round, oval or any other unconventional shape.

A new Robocombi takes the labelled device and transfers it to the machine of the supplier “Waldner”, which puts it into the moulds with the thermoformed cases.

"This has been a fantastic team effort between Marchesini Group, Waldner and GSK Teams delivered through the adversity of Covid challenges"

Nigel Wood, Eng. Capital Dir. GSK BC

Once sealed, the cases with the devices reach the MA 255 continuous-motion horizontal cartoner with Robocombi, which puts them into the carton together with the information leaflet. The cartoners in the MA family are one of the Marchesini Group’s masterpieces: impressively versatile machines that can package the widest variety of shapes and sizes for both the pharmaceutical and cosmetic industries.

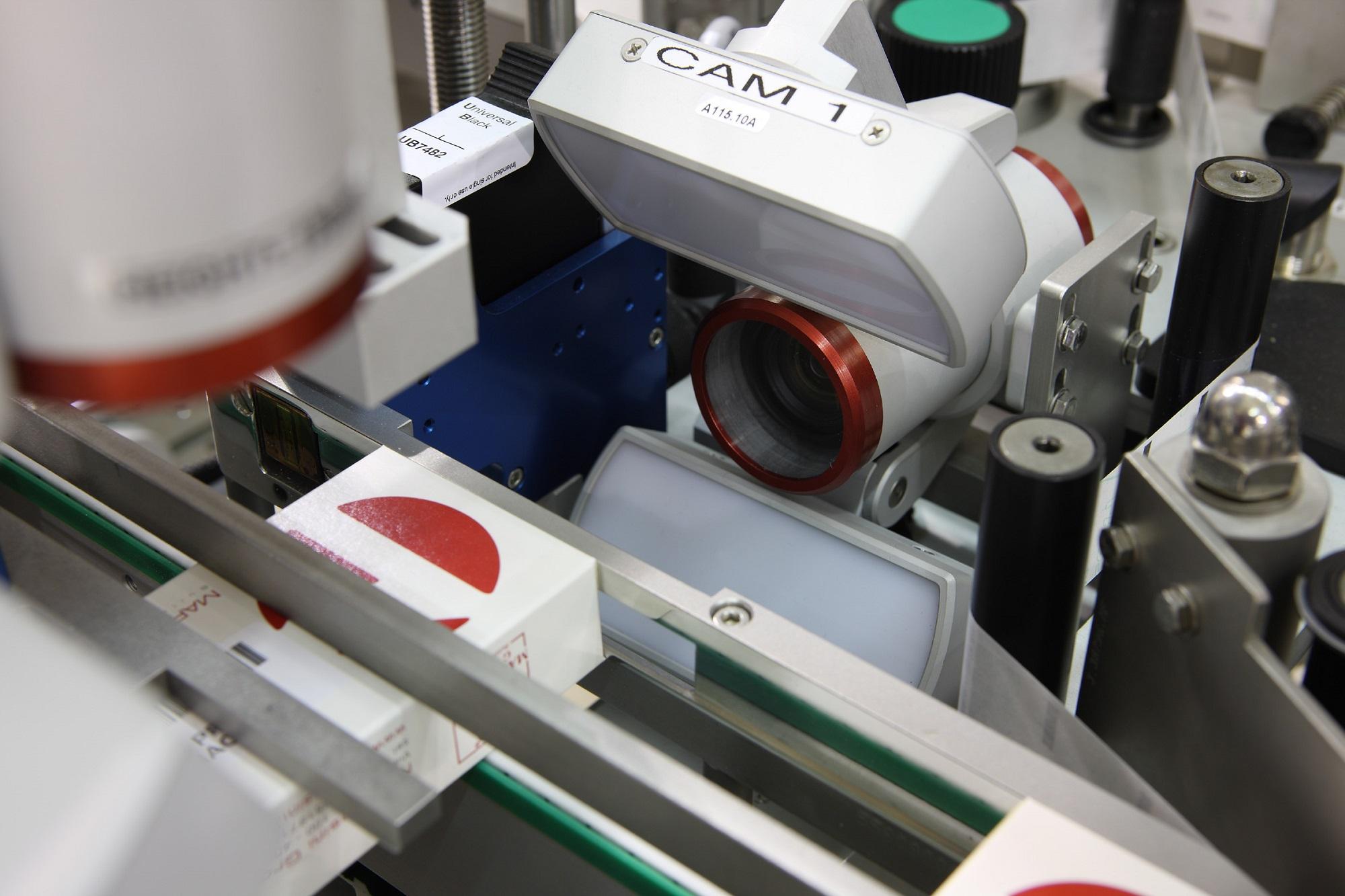

The cartons are then weighed on an external weighing unit and transported towards the labeller BL A-420, which performs the serialization, stamping and sealing operations. Thanks to its outstanding versatility, the BL A-420 unit can fit all types of printing and vision systems currently available so that all the drugs packaged have their own unique code.

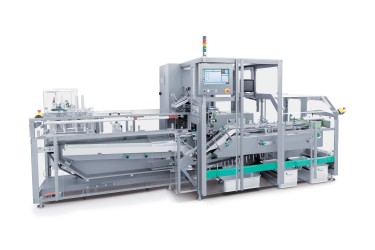

The MCP840 TT monobloc casepacker-palletizer equipped with a Gigacombi completes the packaging process. The MCP840 TT has a very small footprint and can handle a wide range of cartons, even those larger than average, and meets all the requirements related to drug serialization and traceability.

Both the labeller and the casepacker-palletizer are fitted with Sea Vision systems to satisfy the international regulations for visual control and labelling for fully serialised product supply assurance.