Corporate

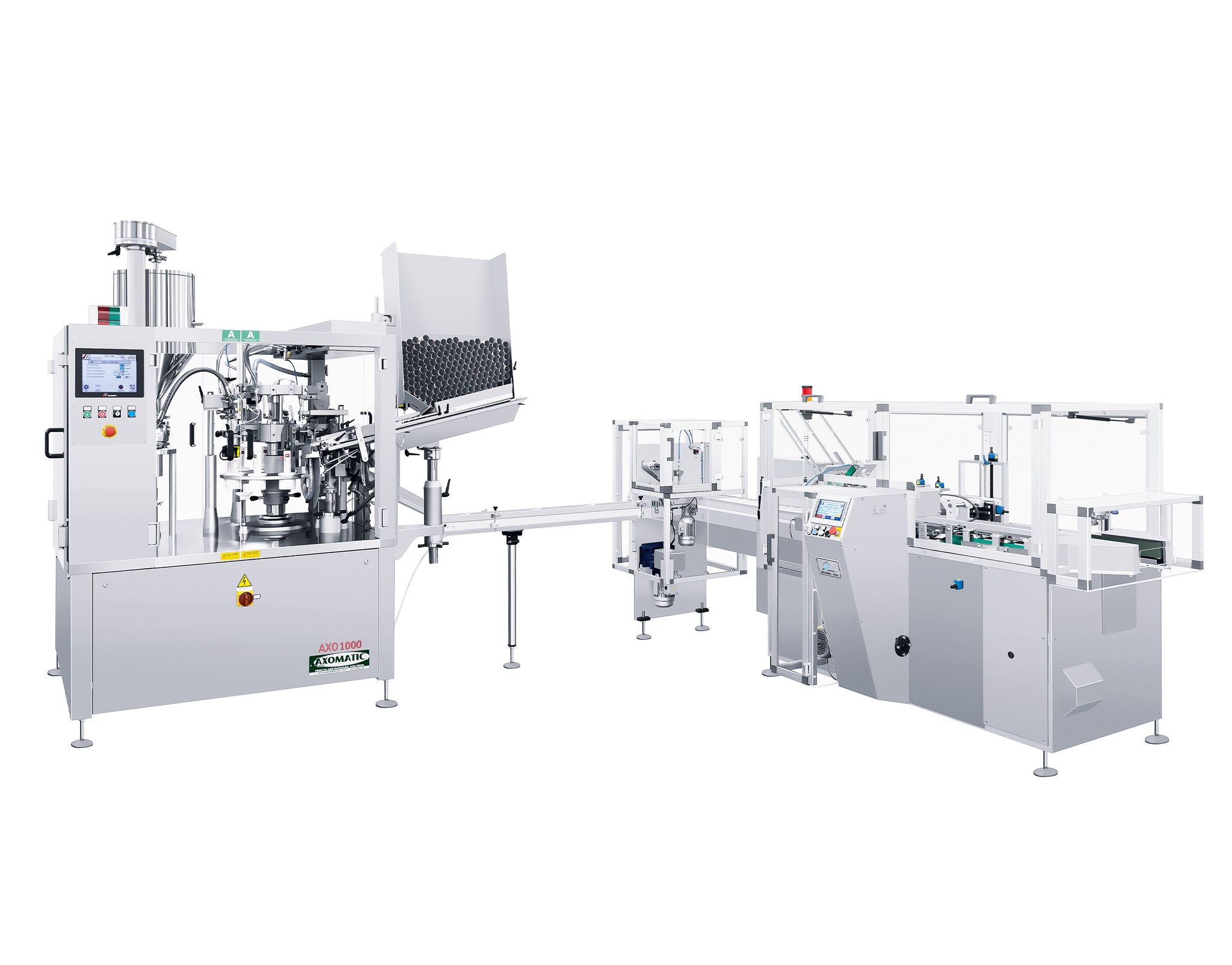

A Bulgarian contractor contacted Marchesini Group Beauty for a solution able to fill and package tubes of herb-flavoured toothpaste on behalf of a Russian household and oral hygiene products company. The line supplied, consisting of the Axo 1000 standard rotary tube filling machine and the V106N automatic horizontal cartoner, is an important milestone in the cosmetics sector, which is ancillary in comparison to the core pharmaceutical sector.

The demonstration of this diversification strategy is the opening of the Group’s new Beauty Division: 5,000 square metres of new facilities developed at the Pianoro Headquarters which are home to offices and the production department for all of the Group’s cosmetic operations.

Upline is the Axo 1000 standard rotary tube filling machine, part of the Axomatic technology family for automatic filling and closing of regularly and irregularly shaped plastic, laminate and aluminium tubes. These machines work with mechanical gripper sealing systems for aluminium tubes and with hot gripper/hot air systems for laminated and plastic tubes. All allow rapid size changes and dosages from 3 to 450 ml.

Options available include automatic tube loading from a magazine, plus customizations depending on the container. Outputs start from 1,000 pcs/h and reach up to 21,000 pcs/h. The Axo 1000, specifically, offers an output of 75 pcs/min (4,500 pcs/h).

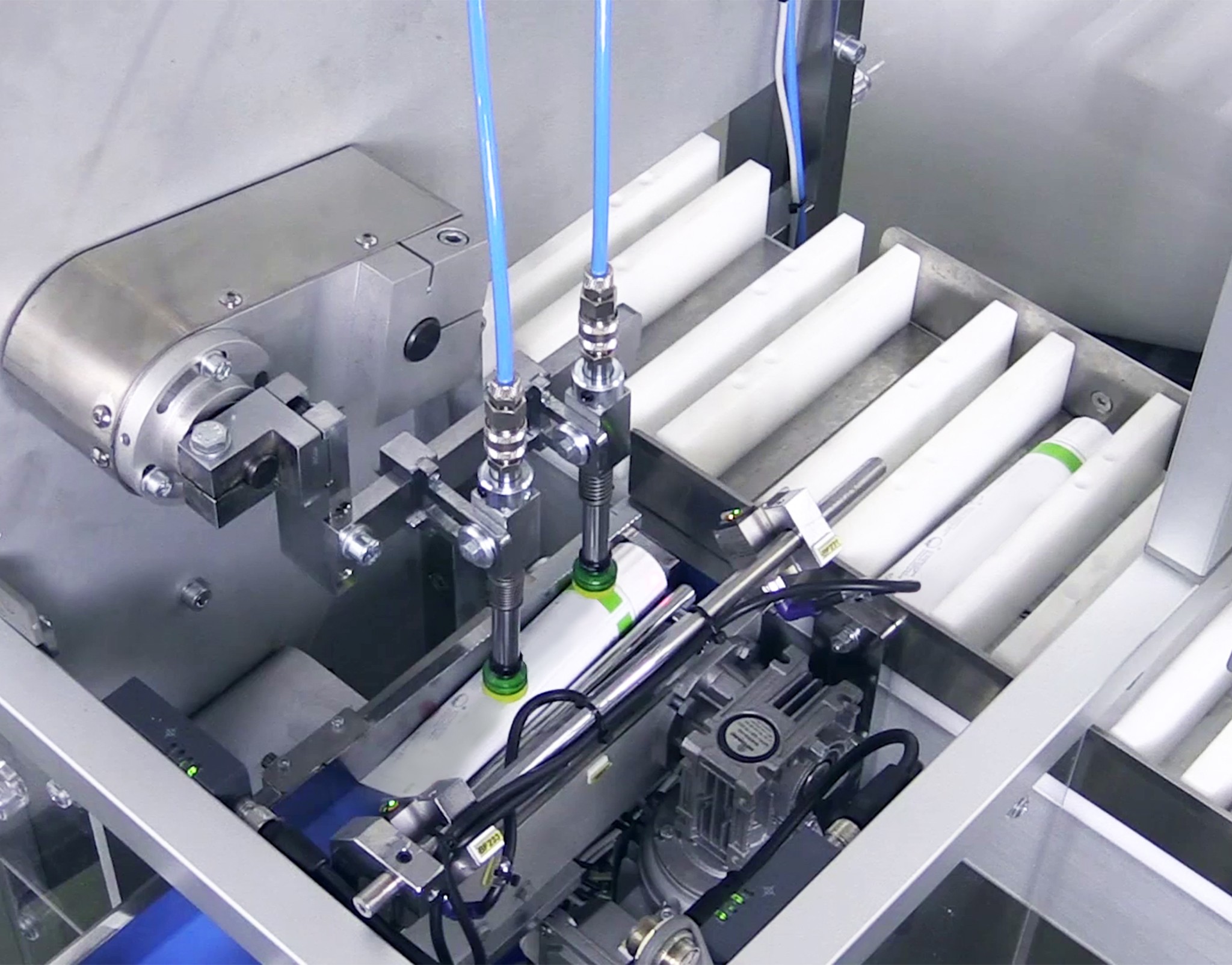

After being filled with 100 ml of herb-flavoured toothpaste and sealed, the tube is transported to the V106N automatic horizontal cartoner designed by V2 engineering, a Marchesini Group Beauty brand. The new V106N model has a redesigned casing and some new mechanical components, while retaining its compact design. This solution is ideal for packaging small-medium sized products at medium-low speeds (up to 70 cycles per minute) for the food, cosmetics, pharmaceutical and non-food sectors.

The V106N operates on an alternating cycle using pre-glued cartons taken from a magazine. Size changes are modern and functional, performed with the assistance of digital indicators. The closing systems available are tuck-in, hot-melt and mixed. Finally, V2 engineering’s numerous years of experience has allowed it to create automatic feeding systems specifically designed for the product to be processed.

Axo 1000 main features:

Advantages and options of the V106N: