Corporate

During the last few years the Brazilian pharmaceutical market has undergone major changes which are directing the demand for packaging machinery towards more and more flexible technologies, able to withstand very intensive production cycles and enable extremely high-speed product changes.

To respond to the strong local demand for medicinal products, Vitamedic - a fast-growing Brazilian company in the Grupo Jose Alves, which operates in the beverage, food, education and logistics sectors - asked us to supply an Integra 520 robotised blister line.

The line delivers unprecedented flexibility thanks to the blister production technology used, the integrated system for transfer between primary and secondary packaging sections, and the new-concept cartoner with innovative carton opening and pusher unit. The end result is an ideal solution, guaranteeing high outputs of stacked blisters combined with very simple cleaning and size change, as well as quicker ramp-up and a technology which can be updated over time.

We at Marchesini Group assign great strategic importance to the partnership with Vitamedic: this is the first supply of an integrated, robotised blister line on the fast-growing Brazilian market, destined to gain more and more importance in the Group's expansion strategies.

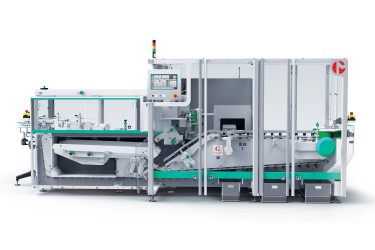

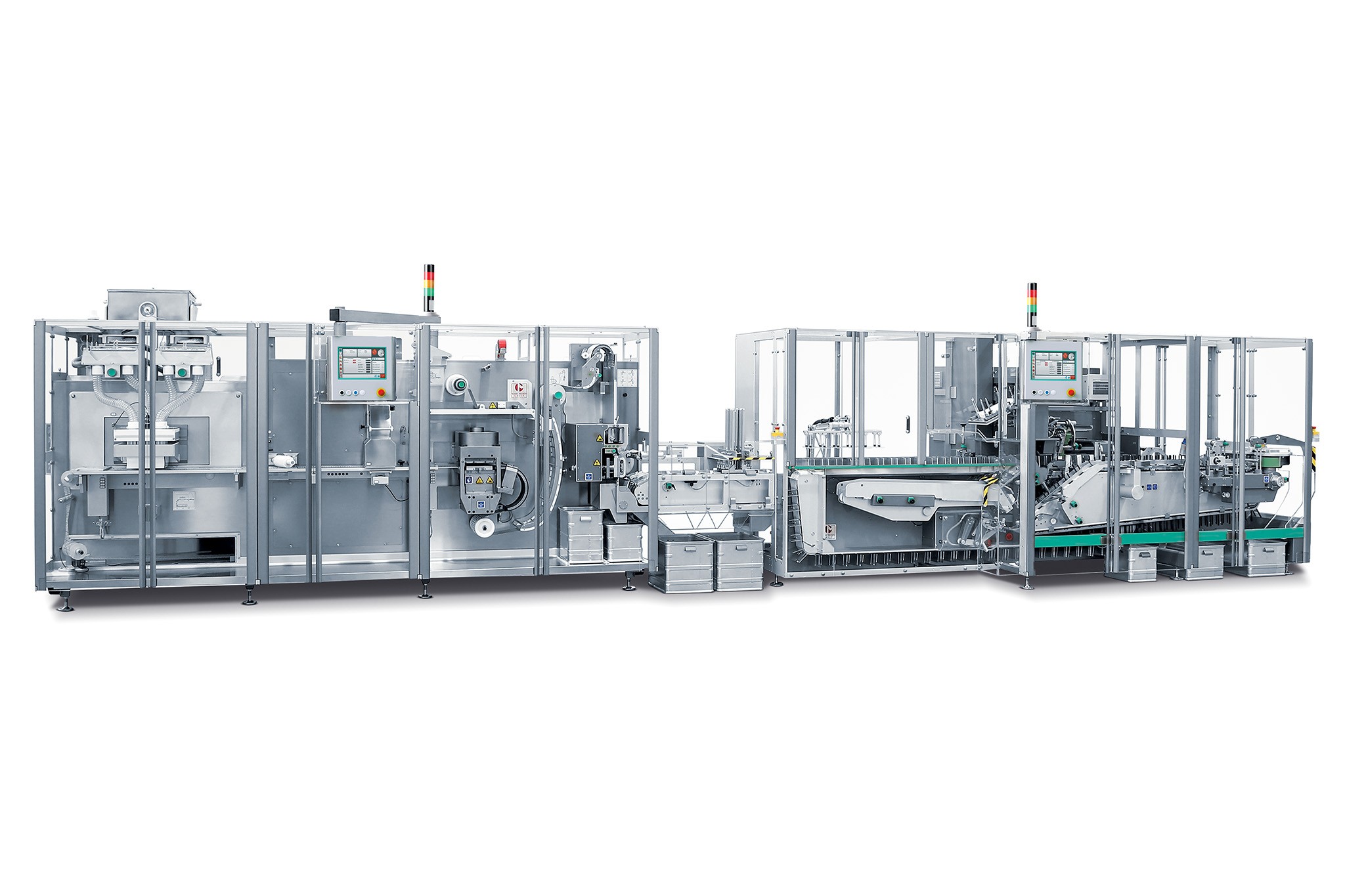

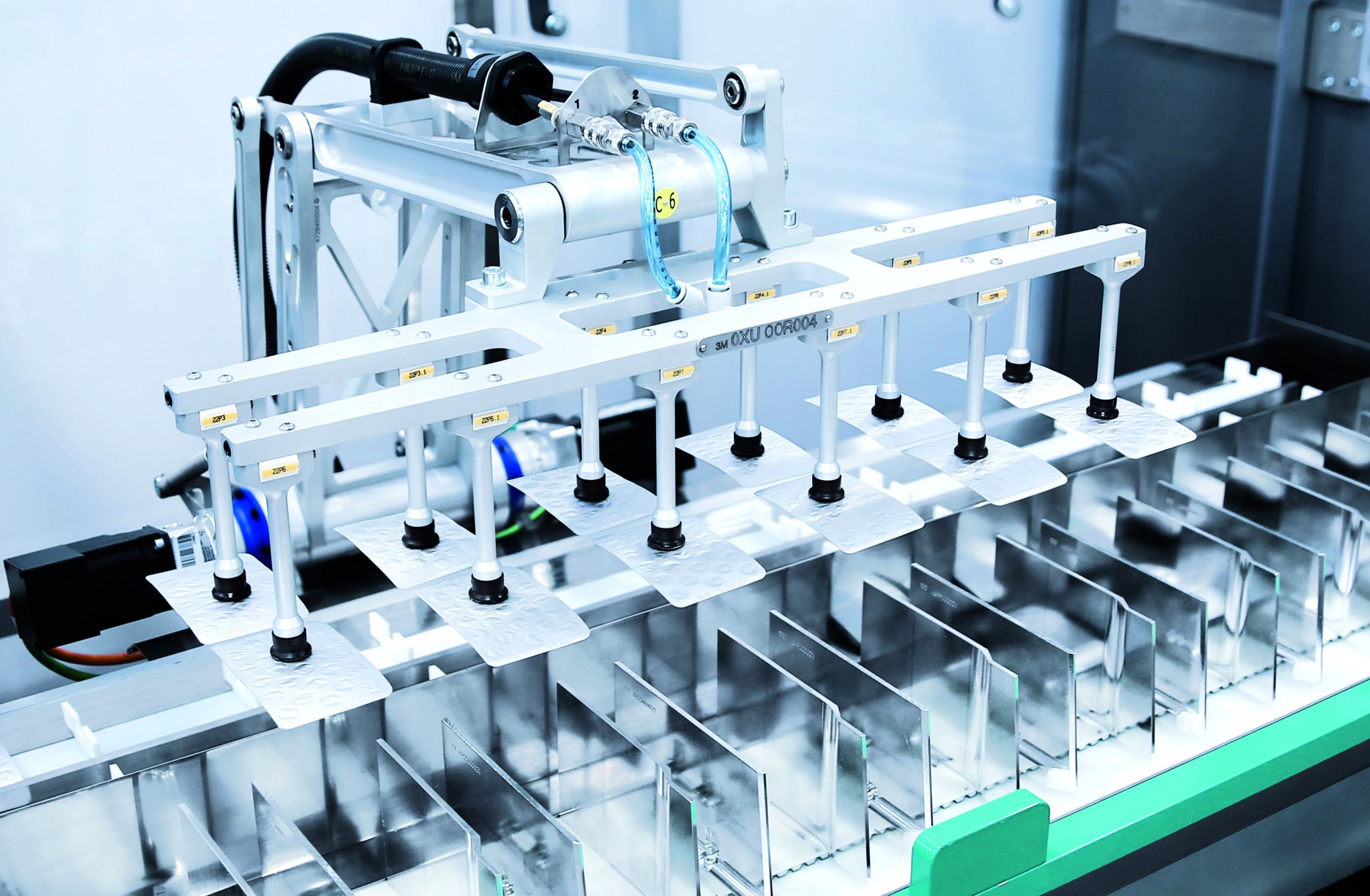

Integra 520 is an integrated, robotised line for packaging blisters in cartons. It is a compact line, with total length only just over nine metres and a totally balcony-style structure, comprising two sections, a thermoforming machine and a cartoner, able to produce up to 520 blisters (in PVC/PVDC/PET/aluminium, Aluminium/aluminium, mono-material and other materials) and up to 260 cartons per minute.

Specifically, the Vitamedic line automatically packages solid products (tablets and rigid and softgel capsules) in PVC/ALUMINIUM blisters, which the integrated Robocombi robot transfers to the cartoner, for the production of various forms of carton.

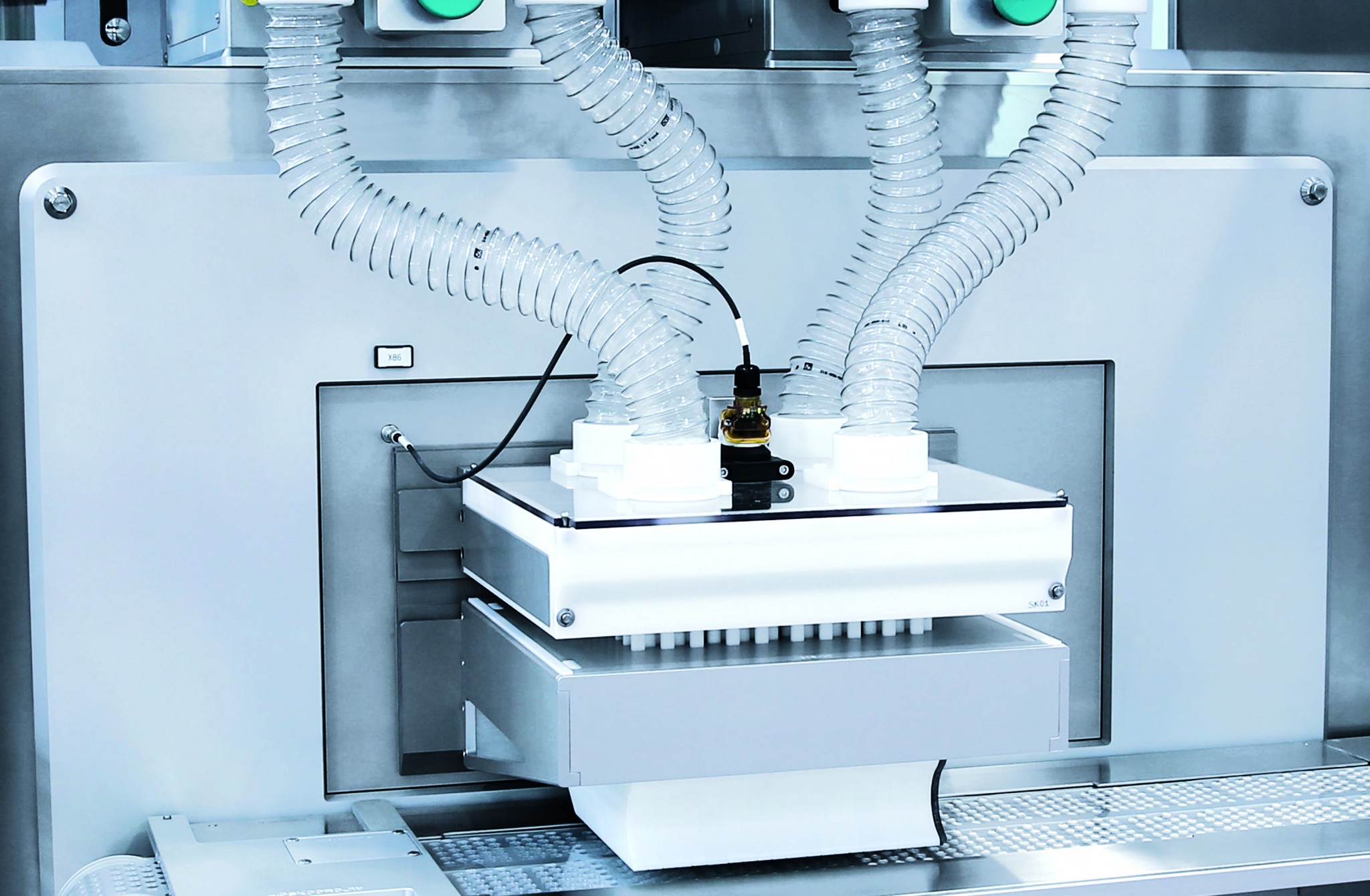

Product infeed

Integra 520 can be fitted with different product feeders (Dedicated high speed (HS) with Pulsar patented release system, Multiplex continuous system and Universal) depending on production characteristics and requirements. The Vitamedic line is fitted with one Multiplex and one high-speed inclined Universal feeder enabling automatic product feeding at the rate of 450 - 500 blisters per minute depending on size.

Cartoning

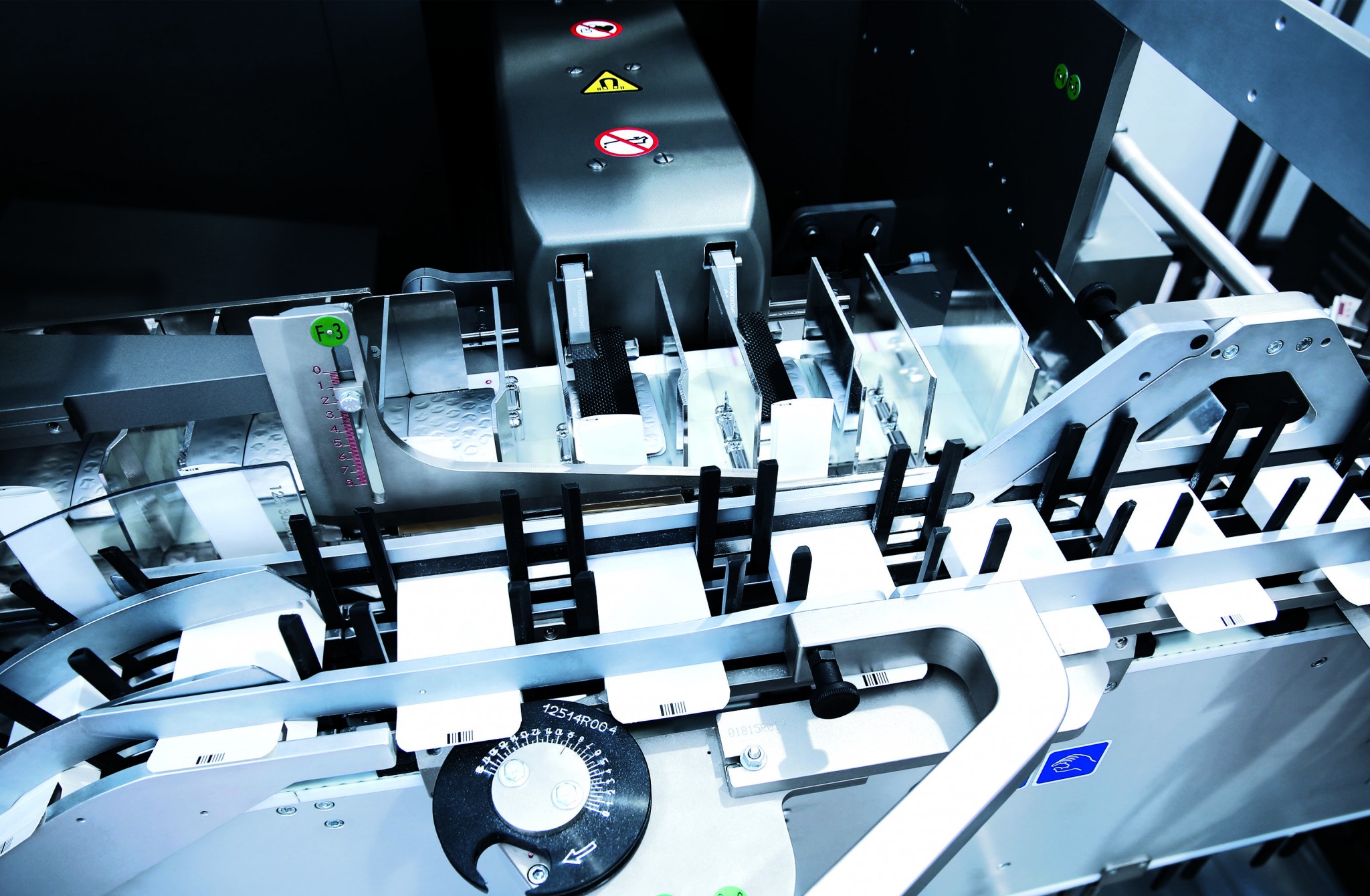

The cartoner used is an MA 260, previously the star of the Marchesini X DAYS: an amazingly versatile machine which, together with the rest of the range, has helped to make the Marchesini Group known worldwide.

The MA 260 is designed to accommodate all possible closing systems, such as tucking, reverse or aeroplane tucking or glued end flap.

The size change components have been designed in blocks for quicker, easier changeover, trouble-free even for unskilled users. The Vitamedic machine features glued flap carton closing.

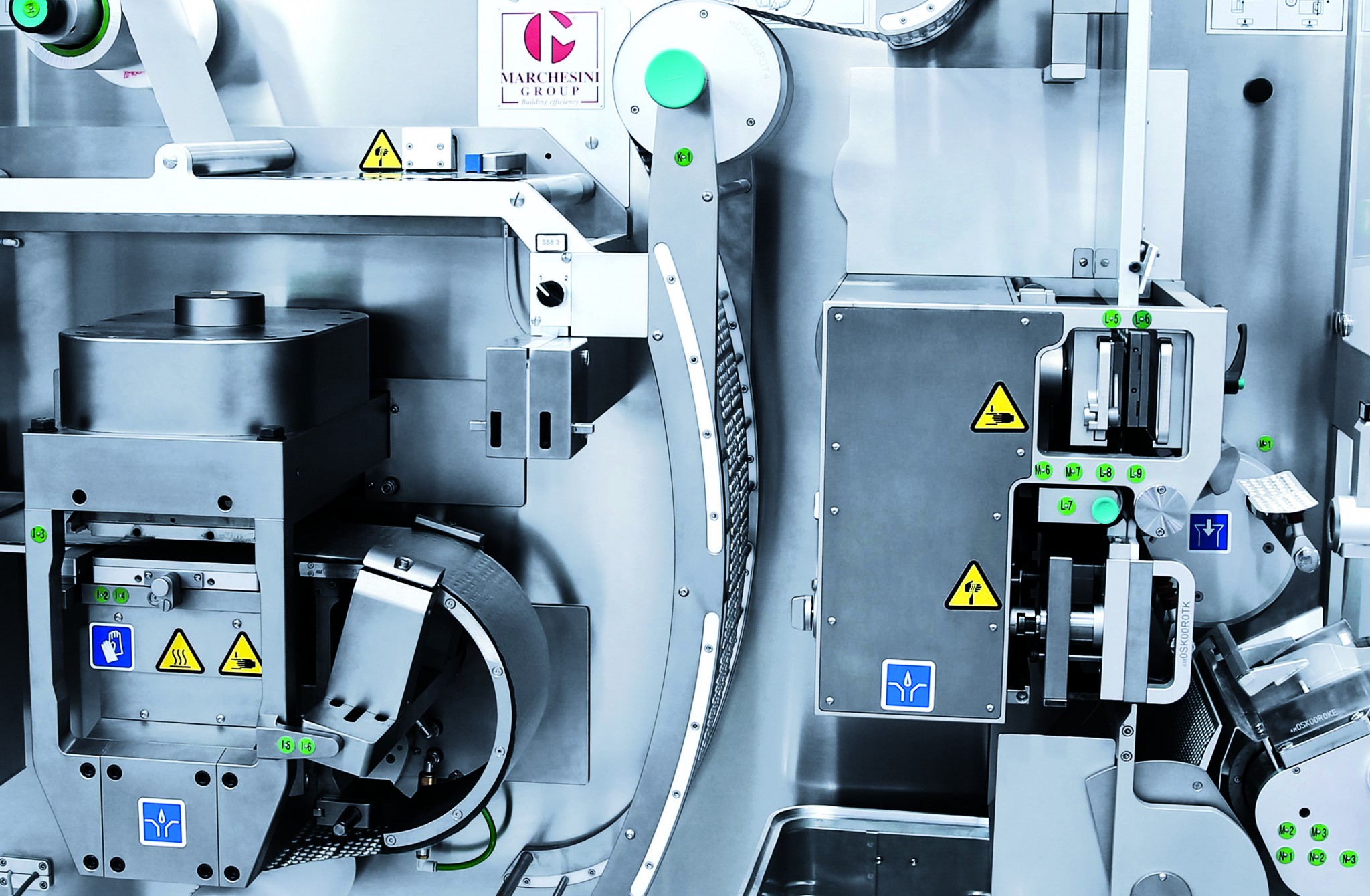

On-board Harlequin

The machine incorporates Harlequin, the colour vision system developed by the partner SEA Vision for the inspection of tablets, capsules, pills and powders packaged in pharmaceutical blisters.

Serialisation and end-of-line

Serialisation is entrusted to the Print and Check BLA 309 machine, which enables the installation of Track & Trace devices such as inkjet and laser printers and the relative cameras to print and then verify 2D codes with the relative readable characters on the side flaps or top of the pack.

The Vitamedic line is completed by the MC 820, a versatile, flexible horizontal case packer specific for the pharmaceutical market, able to meet all needs relating to the serialisation/aggregation and traceability of medicinal products. This compact machine is able to process a wide range of cartons, even of above-average size. MC 820 is ideal for Track & Trace purposes as it can be integrated with all printing, traceability and vision systems on today’s market.

Discover EXTRA, the platform to watch all Marchesini Group Digital Events.

Discover EXTRA, the platform to watch all Marchesini Group Digital Events.