Corporate

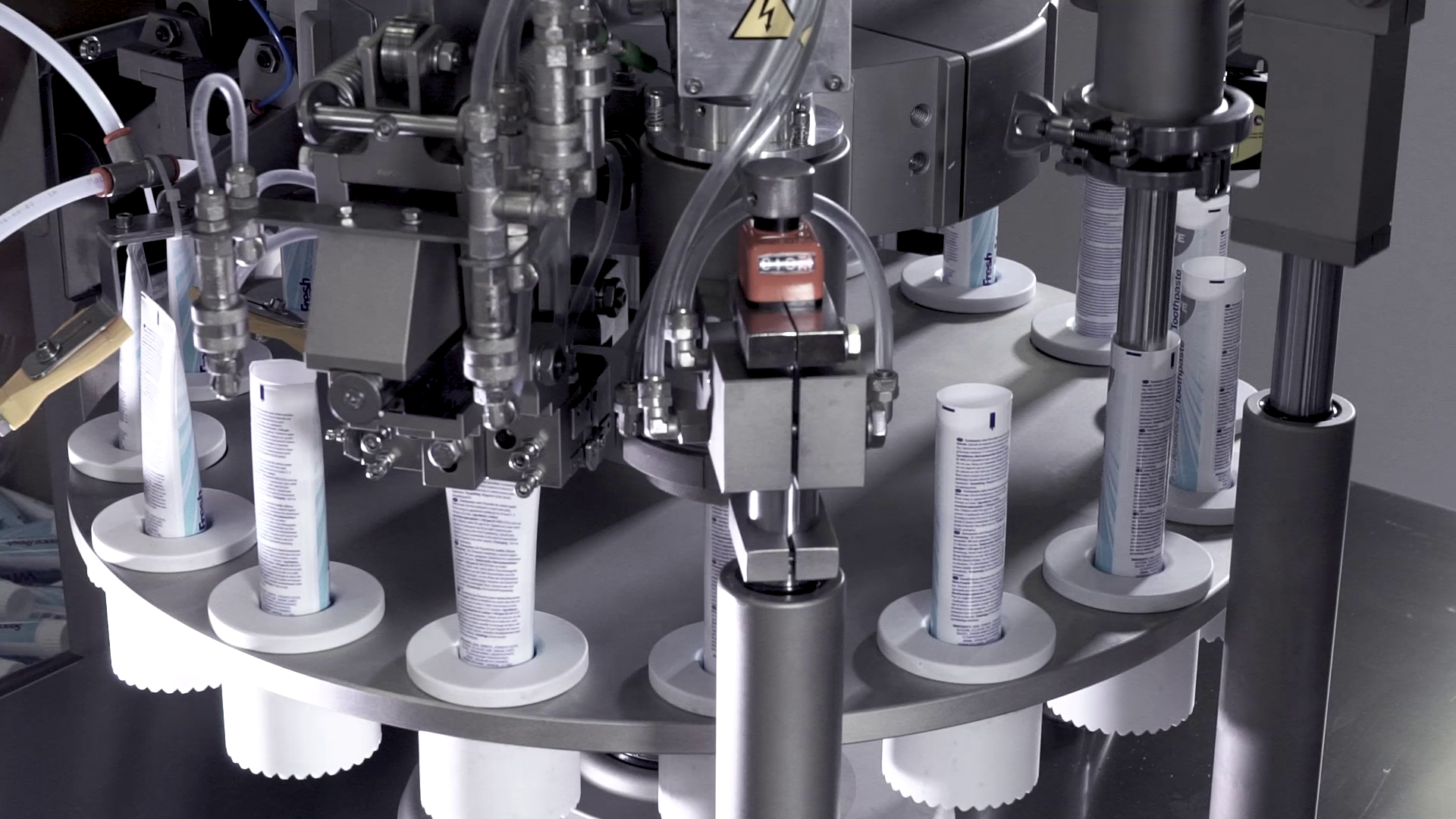

One of the latest solutions developed by Axomatic – Marchesini Group Beauty’s flagship brand – is a stand-alone Axo 1600 machine that can fill tubes with toothpaste in two or three colours. It is an important new addition to the cosmetics sector, which is ancillary to the core pharmaceutical sector. The opening of the Group’s new Beauty Division is a testament to this diversification strategy: 5,000 square metres of new facilities constructed at the Pianoro headquarters, home to offices and the production department for all of the Group’s cosmetic operations.

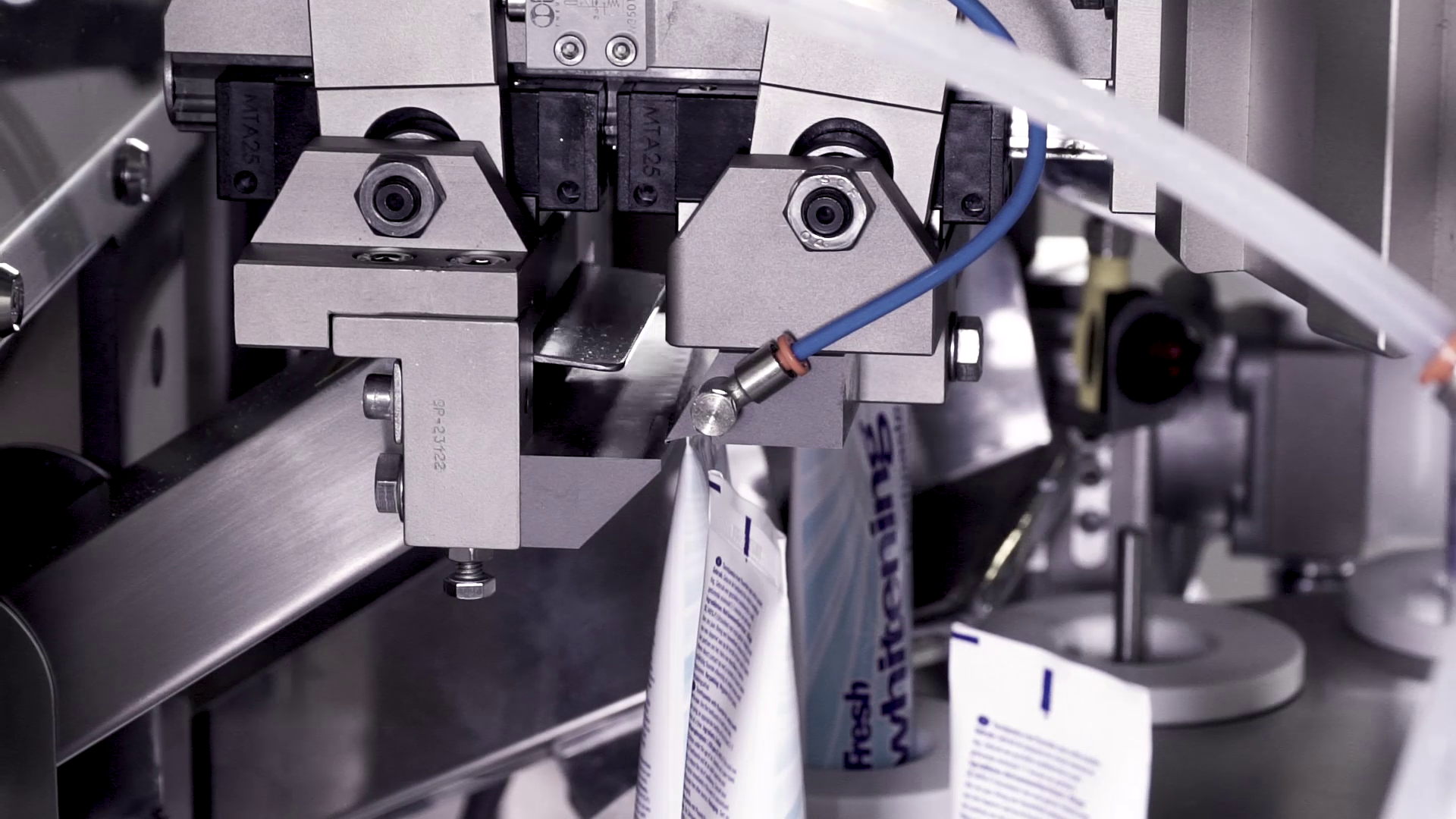

The Axo 1600 standard rotary tube filling machine is part of the Axomatic technology family for automatic filling and closing of regular and irregular-shaped plastic, laminate and aluminium tubes. These machines work with mechanical gripper sealing systems for aluminium tubes and with hot air systems for laminated and plastic tubes. All allow rapid size changes and dosages from 3 to 250 ml (optional up to 450 ml) and operating speeds of 1,000 to 15,000 pieces per hour. In this case the Axo 1600 processes 125 ml plastic tubes at a speed of 50 pieces per minute for filling two-colour toothpaste. Once filled and sealed, the toothpaste tube continues its journey along the packaging line.

Plus Axo 1600:

Axo 1600 options: