Corporate

In 2019, we handed over a packaging line for botulinum vials, mainly for pharmaceutical use, to a French customer. The line is up and running, along with another Marchesini vials packaging line, at a factory in Wales recently opened by the customer. This complex project came to life in 2016 and was completed following its consignment in 2019.

The vials are manually loaded from a tray onto an accumulation turntable. From here, they are picked up by a conveyance carousel, interchangeable by size, that takes them to the labelling unit on the machine upstream. The high speed labeller RL-F300, with “Fail Safe” operating logic, ensures that only “good” vials are guided to the machine downstream, whereas the others are detected and rejected. It also has self teach-in and storage systems for the label data.

The head is equipped with a label overprinting system and overprint presence control device; the unit also has a device that makes sure the vials actually have the label. These two devices will reject any vials without a label or vials on which the label has no overprint.

Once the labels have been applied, Marchesini’s robots come into action, all designed and produced in-house. The first Robocombi opens up and handles the cardboard trays, which have been tailor-designed by Marchesini Group for this specific customer. The second Robocombi handles the labelled vials and puts them into the cardboard trays.

To conclude, the third Robocombi takes the tray containing the booklets and vials and, with two special labelling heads apply a glueless label containing the codes used to divide the Botox injections. After that, the tray is moved to the MA155 cartoner.

The cartons continue towards the BL-A420 labeller where the product is serialized, stamped and sealed. The BL-A420 is incredibly versatile and can accommodate all types of printing and vision systems available in the market, giving every single packaged pharmaceutical its own unique identity.

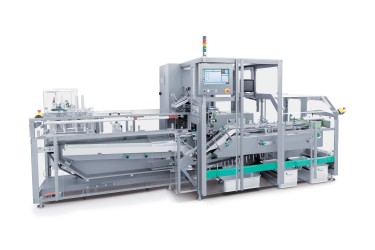

The packaging process ends on the MC 820TT compact horizontal case packer, which is able to handle a wide array of cartons, even those larger than average, and meet all the requirements related to pharmaceutical serialization and traceability.

Both the labeller and the case packer are equipped with SEA Vision monitoring systems to satisfy the visual and labelling control requirements defined by various international regulations.