Corporate

The partnership between IBSA Group and Marchesini Group dates back to the late 1970s, when Swiss pharmaceutical company Inpharzam - founded under the general management of Dr. Arturo Licenziati - set about looking for a company to supply a line for sorting sachets of granules.

The chosen supplier was a small Bolognese engineering firm owned by Massimo Marchesini, who was determined to make a name for his company in the difficult pharmaceutical packaging machines market, which had until then been dominated by a few big players.

The first production equipment supplied by the company was installed in 1980. It was a sachet filling machine able to fill four sachets per stroke, combined with a cartoner. After a rapid increase in demand, these two machines were followed by a second six-way sachet filling machine, with corresponding cartoner.

In 1985, Mr Licenziati decided to set up on his own by acquiring a small Swiss pharmaceutical company, IBSA SA (Institute Biochimique SA) of Lugano. Licenziati took some trusted technicians who had previously worked with him to the new company. This meant that the tried and tested relationship with Marchesini Group was not interrupted – quite on the contrary, it was only strengthened, thanks to orders for further machines and lines to handle the gradual development of new formulations.

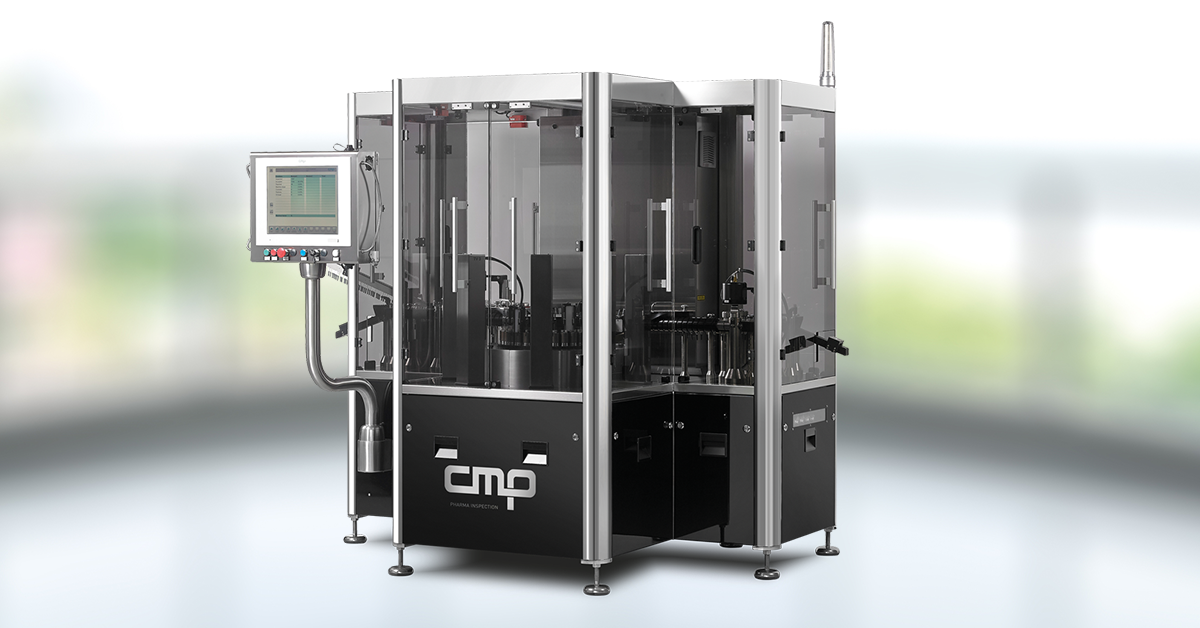

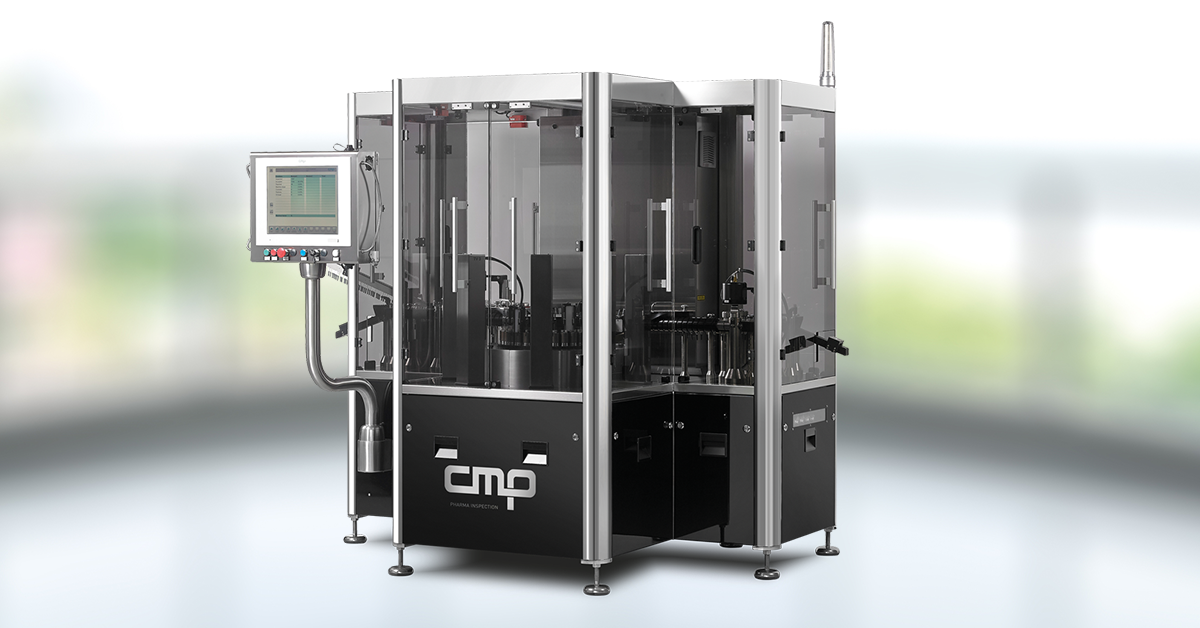

Over time, this partnership between the two groups was further strengthened, evolving into a long-standing and privileged relationship: over the last nineteen years, Marchesini Group has supplied the Swiss company with cartoning machines, labelling machines, blister packaging machines, machines for primary filling and secondary packaging, as well as automatic case packers and tube filling machines to meet specialised and complex production requirements (soft capsules, syringes, traditional ampoules produced in aseptic conditions). The Italian division of IBSA invested 15 million Euros in purchasing these solutions – high-tech equipment designed to perform very specific production tasks, still relatively rare within the Italian pharmaceutical sector. Amongst the most recent orders are two machines from CMP Phar.ma, the Marchesini Group brand specialised in the production of control and inspection systems for pharmaceutical products.

Today, the IBSA Group employs over 2,000 people, boasts a range of pharmaceutical products which covers ten different treatment areas, is the holder of 82 groups of patents, has a product presence in over 80 countries around the world, and in 2019 generated turnover of more than 600 million Euros between its Italian and Swiss plants.

Marchesini Group’s rapid growth trend continues, with turnover reaching 441 million Euros in 2019. Some of its most important recent sales include the purchase of a packaging machine for the Sputnik vaccine by a Russian customer; the shipment, soon to be repeated, of CMP Phar.ma machines to Mexican customer Liomont for packaging of the Astra Zeneca vaccine; and the creation of a Beauty Division: 5,000 square metres of new plant floor area to strengthen the Group’s position in the cosmetics sector.

IBSA Farmaceutici requested a customised machine for the inspection of pre-filled syringes with products in both liquid and gel form (hyaluronic acid) from CMP Phar.ma, the Marchesini Group brand specialised in inspection and control solutions for pharmaceutical products.

IBSA Farmaceutici requested a customised machine for the inspection of pre-filled syringes with products in both liquid and gel form (hyaluronic acid) from CMP Phar.ma, the Marchesini Group brand specialised in inspection and control solutions for pharmaceutical products.