Corporate

Designed to comply with cGMP regulations, the INTEGRA 420 and 420V feature a balcony structure to improve accessibility.

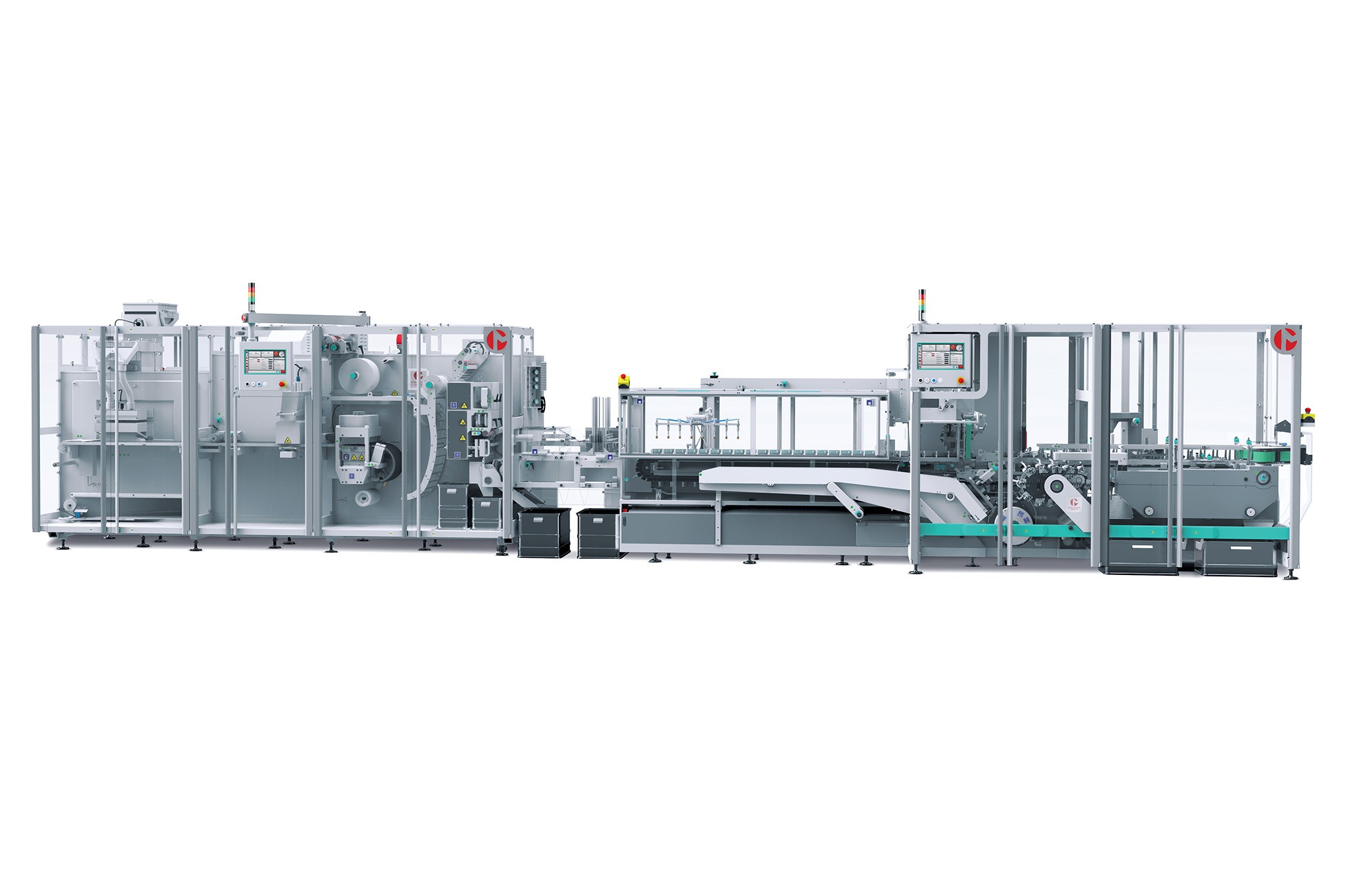

The machines are composed of two main sections, the blister Thermo/cold-forming unit and the cartoning section.

Focusing on the blister part, it features an ergonomic working area thanks to the rear position both the forming reels and the preheating and forming station. This also allows a compact footprint, as required of today’s industry.

Multiple options of product feeding units are available in order to perform any kind of production.

Sealing, coding and cutting operations run over servo driven independent groups.

The ROBOCOMBI transfers, pursuits and stacks the blister into the cartoning section.

Main features:

Featured Model: INTEGRA 420V

Blister section available as stand alone machine.

| OUTPUT | |

|---|---|

| Speed: | Up to 420 blister/min |

| BLISTER SIZE | |

| Width: | 420: 30 - 86 mm 420V: 30 - 66 mm |

| Height: | 3 - 12 mm |

| Length: | 70 - 140 mm |

| CARTON SIZE | |

| Width: | 420: 35 - 90 mm 420V: 25 - 70 mm |

| Height: | 420: 15 - 90 mm 420V: 15 - 85 mm |

| Length: | 420: 75 - 150 mm 420V: 65 - 150 mm |

Receive the machine brochure in pdf format, directly in your e-mail inbox.