Corporate

At Interpack Marchesini Group will exhibit an hyper-technological blister line composed of Integra 520 V, and of the new labeller BL A 525 and the new fast bundler FA 04 - which are both built to manage the flow of 500 cartons per minute incoming from the cartoner MA 500. The packaging process ends with the new casepacker for Track and Trace MC 820TT, which puts the bundles into cases.

This line - able to deliver 520 blisters and 500 cartons per minute - is a perfect solution to pack blisters and cartons at high speed.

Integra 520 V blister line and MA 500 cartoner

Integra 520 V - the fastest of the robotized integrated blister line produced by the Marchesini Group - combines two machines: a thermoformer and a cartoner. Integra 520 V features not only the innovative functions of Integra 320, but also new pushers, a drum-type carton opener to deal with high speeds and a new leaflet pick-and-place system.

The carton pick-up and opening unit has been built according to the operating principles of all the cartoning machines of the Marchesini Group, with a drum that picks up the cartons and opens them out, holding them firmly and accurately even at high speeds. The cartons are then taken directly to the carton conveyor belt. Access to the forepart of the machine has been improved, making it handier for operators to have an even better overview of the whole machine.

The leaflet-feeding unit is enclosed by guards to minimize noise. The GUK feeding unit is in an ergonomic position (lower than the previous models) to ease leaflet loading. In view of the high processing speeds involved, a new rotating pick-and-place unit has been designed and installed to transfer the leaflets to the pushers.

Blisters are inserted into the cartons by MA 500, an ingenious product insertion unit which represents the highest mechanical innovation of the Marchesini Group. Two separate combined units, pusher and blade, insert the product into the carton with impeccable precision, even at high speeds. A simple input from the display will rise the unit automatically when the machine has to be cleaned or serviced.

BL A525

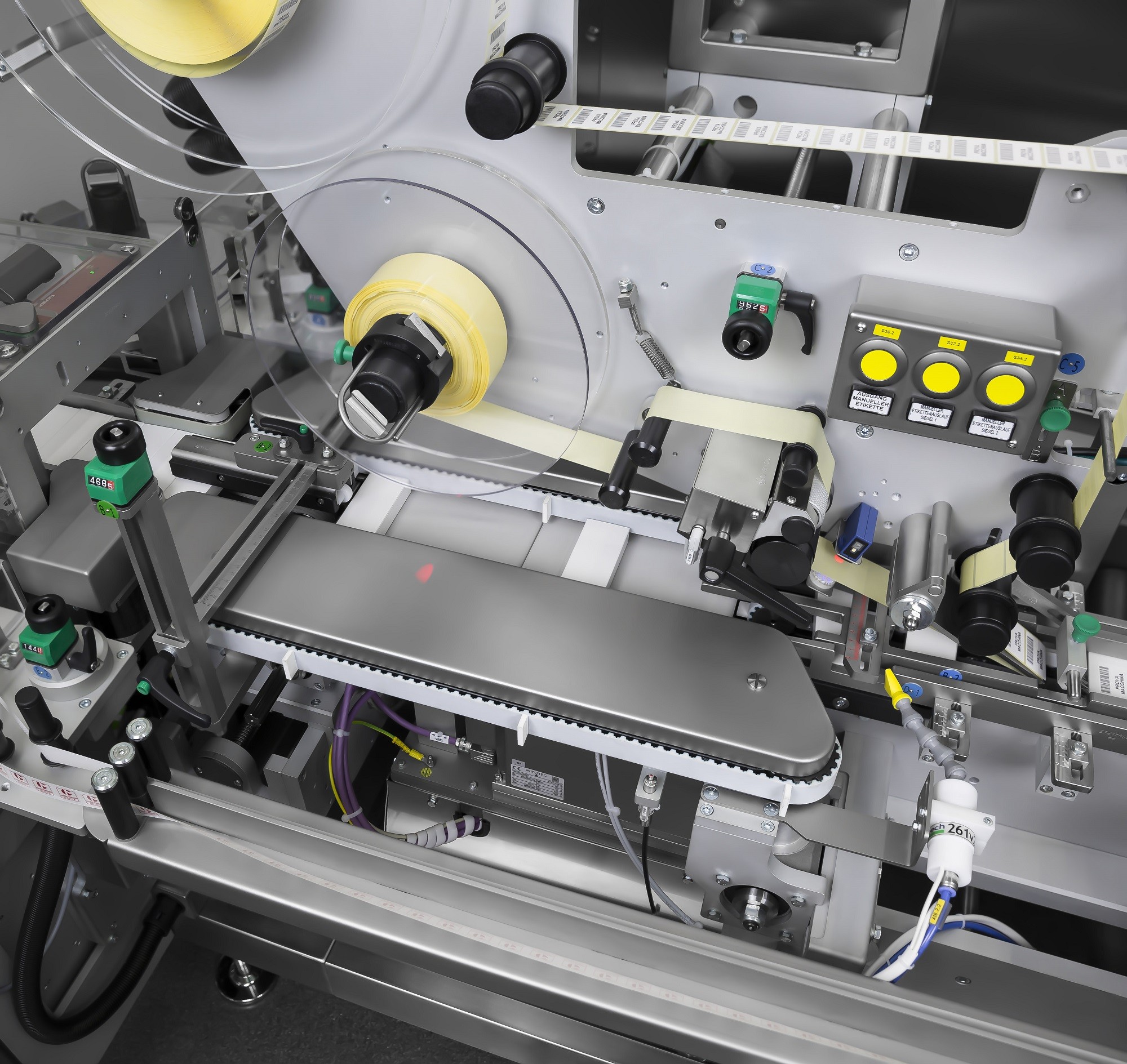

The new BL A525 has been designed and developed by Neri Division to be integrated with the Integra 520 V.

The cartons coming from MA 500 cartoner are fed in-line and accumulated on the inlet belt in order to ensure a smooth flow of products even at high speeds. A timing device positions and sets the cartons apart correctly on the toothed belts with adjustable opening, which also prevent slipping. The function of the timing device is to set the cartons at the correct distance apart: this system is synchronised with the speed of the whole conveyance system and there is no need for any size change-over adjustments once set-up.

The first operation to be performed after the cartons have been positioned is that of applying the optical seal or vignette on the upper panel of the cartons; then the unique 2D code (Datamatrix) and the corresponding human readable data are printed on the side flaps and sometimes on the upper panel. The unique code identifies and makes it possible to track each carton.

A camera then verifies both the codes and the readable data. Once the code has been completed in this way, two self-adhesive Tamper Evident seals are then applied on the corner closing points of the cartons.

All the label dispensing units are driven by servomotors, whose speeds are synchronised automatically with those of the carton conveyance system.

During these phases, the use of the “Fail Safe” operating logic means that only “correct” cartons are sent to the machine downstream, while the others are identified and rejected.

The BL A525 is incredibly flexible and can accommodate all the printing and vision systems available on the marketplace, to reach a rate of 500 cartons a minute. This peculiarity makes the BL A525 the most suitable and complete machine for tracking, serializing and labelling pharmaceutical cartons, so that they all have their own unique identity.

New FA 04

Downstream from the line is the new FA 04 fast version, which has been developed from the FA 04 classical version. The new unit can handle a production flow of 500 cartons per minute, arranged in 50 bundles of 10 cartons. The machine on show at the fare has a balcony structure so that all the parts involved in the product flow are clearly visible, also to minimise maintenance work and to ensure simplicity of use.

MC 820TT

MC 820TT is a new case packer for Track & Trace needs devised to offer a complete machine for customers’ requirements but also to be offered as a “standard” all-inclusive version.

MC 820TT is fully equipped with a complete and tested system for serialization and data aggregation which includes also a complete vision system and a thermal label printer Zebra. Bundles coming from FA 04 are grouped on the infeed conveyor belt and transported to the pick and place group to be transferred onto the hopper. The serial codes printed on the carton flap are acquired by a camera. In the event of incorrect reading, cartons are picked up and deposited on the front reject belt, keeping re-working and case rejects to a minimum.

After the case is closed, a label - printed in real-time with serialized codes and variable data from the ZEBRA printer - is applied to the case. The label can be applied on one side of the case or in an “L” position, over the edge of the front and lateral side of the case. The labels are applied when the cartons are stationary thereby guaranteeing a uniform position on the cases as well as greater legibility.

Once the label has been applied, a camera checks for precision and also detects the ANSI GRADING. The case is rejected if the case or the label is defective.