Corporate

The new BL A525 CW labeller belongs to the extensive BL A range of versatile and reliable carton tracking and labelling machines. BL A525 CW is designed to produce 520 pieces/minute and therefore to be installed in line with the new Integra 520 V and its cartoner Cinqucento.

The machine showcased at Achema also includes a high speed load cell. After installing it on the BL A420, this load cell has also been installed on the 525 model for the first time, thus boosting the unit’s versatility and performance even further, thanks also to the possibility to install every kind of printing and vision system presently available.

The end result is a high-tech machine capable of weighing, serializing and labelling cartons to give them their unique identity, as requested by current norms.

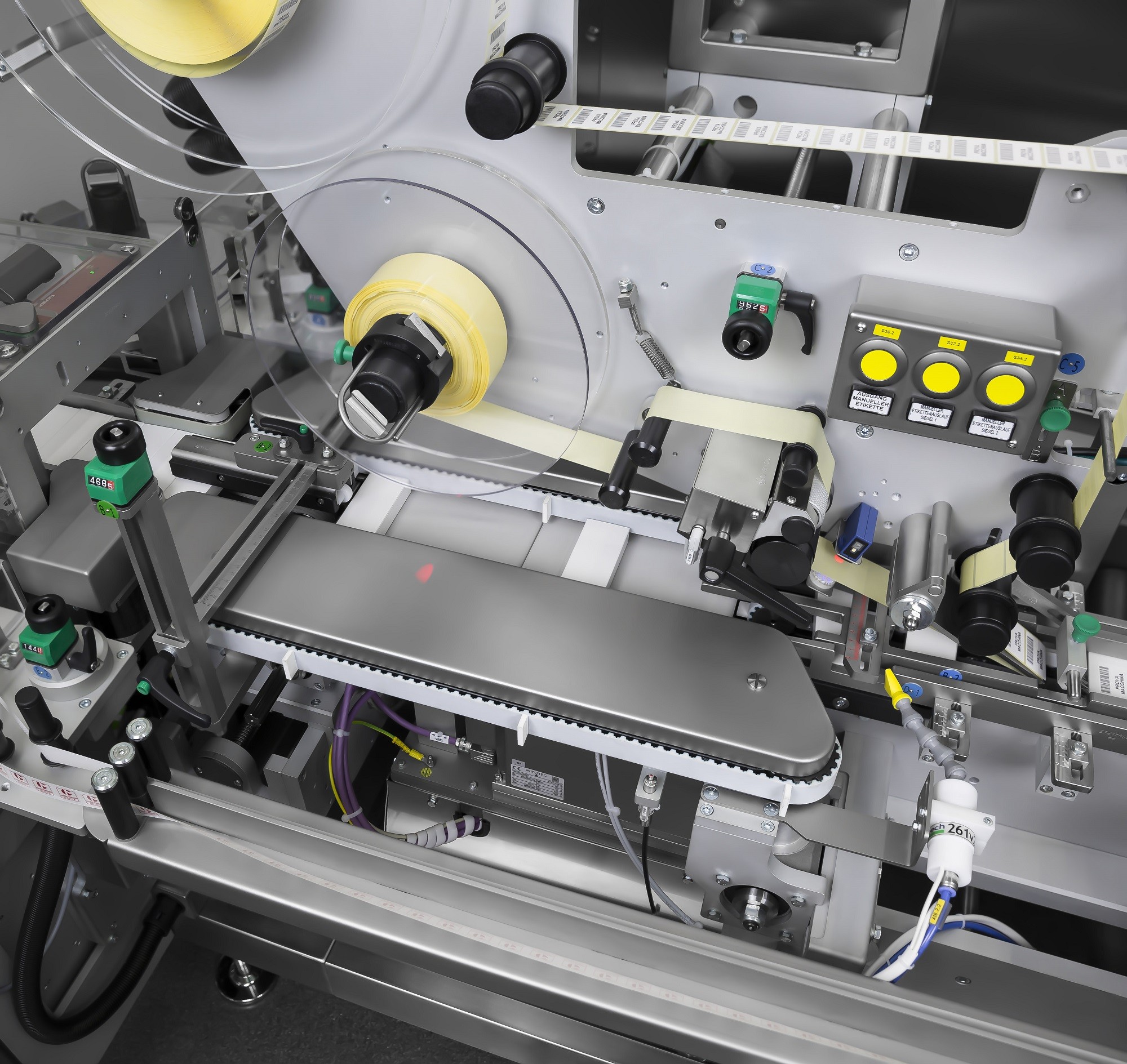

On the BL A525 CW, the load cell is fully integrated into the step conveyance system and can weigh each individual carton at very high production speeds. This system is much more compact than the classic solution (where the weighing unit is positioned in line), and than the versions of main competitors, who use coupled weighing units but which have their own separate conveyor in addition to that of the labeller.

By integrating the load cell into the toothed belt conveyor of the BL A525 CW, this unit is able to exactly identify the position and weight of the individual cartons at any time. If correct, the product moves onto the following stations for tracking, labelling and sealing and the carton is transferred to the machine downstream; if, on the other hand, they are not correct, the carton does not move onto the following phases but is rejected according to a “Fail Safe” logic.

A patented “timing” device sets the cartons at the correct distance apart on the two toothed belts that can be adjusted according to the length of the cartons and that prevent slipping. This special carton timing device is synchronised with the speed of the toothed conveyor and requires no size changeover adjustments.

The following processes are application of the optical-effect label or vignette on the upper part of the cartons and then printing of the unique 2D code (Datamatrix) and corresponding human readable data on the side flaps and sometimes also on the upper flap. The unique 2D code makes each carton individually identifiable and traceable. Both code and human readable data are verified by a camera vision system, after which two Tamper-evident self-adhesive seals are applied on the two closure corners of the cartons.

All the label dispensing units are driven by servo motors, whose speeds are automatically synchronised with those of the carton conveyors.