Corporate

Despite the COVID-19 epidemic, Marchesini Group has never stopped. Our activities are part of the packaging supply chain included by the Italian government as among the essential activities that have remained open.

We are currently producing and delivering packaging machines for vaccines, and in general continuing with customer order deliveries with the help of technologies such as FAT in streaming.

We were the first company in the world to create complete lines for filling and packaging these important products for the pharmaceutical industry. In 2004, a well-known Chinese company commissioned a line that would carry out the whole process of filling and packaging vaccines in a syringe. A few years later, in 2009, the same customer became the first Chinese Big Pharma company to receive authorization to produce a vaccine against the H1N1 virus that caused swine flu and purchased the second complete Syringe Packaging Line from Marchesini. This valuable partnership continues today and we are in the process of delivering three additional vaccine packaging lines as well as other stand-alone machines to update existing lines.

We have also been pioneers in this field in other parts of Southeast Asia, with the installation of a vaccine line to fill, assemble and pack syringes. The line, in operation for five years, represented an important step forward for the local market in the production of vaccines in syringes, which are usually expensive for emerging countries.

Our technology and machines also enabled us to produce lines for pharmaceutical multinational companies involved in the production of antibiotics against the H5N1 virus, responsible for the avian flu.

"We will try, even in this unprecedented moment in history, to be as quick as possible in delivering our machines, while safeguarding our staff’s health," said Pietro Cassani, CEO of Marchesini Group in interviews given to RAI, the Italian state television.

In Italy, where our production plants are located, we recently doubled the production department of Corima, the Group’s division specialised in aseptic packaging technology and machines. Today, Corima has a 12,000 square metre factory at its disposal and aims to respond more completely and quickly to the growing demands of a sector that, given current events, is increasingly strategic.

We supplied a complete standard line for vaccines to a Chinese customer. The line starts with the syringe denester and ends with the wrapping unit and it was purchased for the mass production of vaccines. It was designed and built to guarantee simple size changeovers and consists of the following units: a denester, the plungering and labelling machine Combi 2PL the automatic deep-draw thermoforming unit FBZ 320, the horizontal and continuous-motion cartoning machine MA400 and the wrapper and over-wrapper FA04.

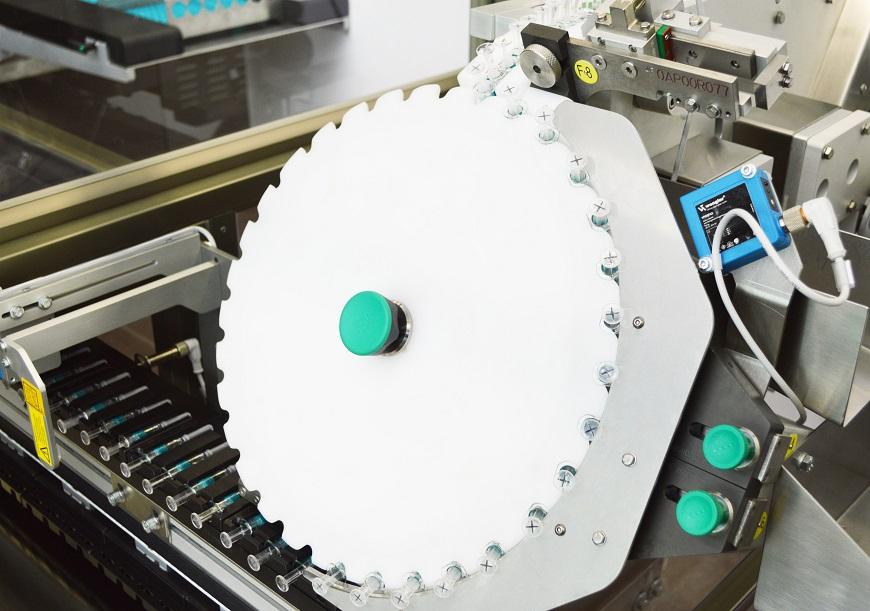

The denester - produced by the Group’s Corima Division, picks up and automatically controls the previously filled and closed disposable syringes. The product pick-up and handling movements are precise and secure, as the unit is also designed to avoid aesthetic damage to the syringes.

The pre-filled vaccine syringes are subsequently assembled with plunger and back-stop and are labelled by the plungering and labelling machine Combi 2PL, equipped with a vision control system.

The syringes then reach the FBZ 320 machine, equipped with Robomaster, a robotized feeding system fully designed and manufactured by R&D within the company. Robomaster, which feeds the syringes to the thermoformer, is able to carry out up to 80 pick-up cycles per minute, with strokes of over 500 mm and always with an extremely delicate touch. Thanks to Robomaster, the whole line works at high speed, has an outstanding loading capacity, simple and fast size changeover process and a large work area.

The quality of the finished product, the outstanding ruggedness and the tool-free size changeover features make FBZ 320 a highly reliable, flexible and user-friendly machine, also thanks to its high-speed die-cutter, which makes it incredibly fast and efficient and simultaneously reduces rejects.

After the thermoforming process, the syringes reach the high-speed horizontal continuous-motion cartoner MA400, which handles up to 300 cartons a minute with one tray in the carton. It combines the advantages of a smaller footprint with increased stability and improved reliability. This machine is equipped with a robotized feeding unit, a three-axe Robocombi with suction pick-up heads, patented by the Marchesini Group, which minimises size changeover operations. This robot picks-up the syringes, stacks them correctly and places them directly into the buckets of the carton packager.

The FA04 wrapper and over-wrapper completes the line. This machine is able to process different combinations of products inside the package.