Corporate

At Pharmintech (3-6 May 2022, Milan) and during Open Door Pharma (2-6 May 2022, Pianoro), Marchesini Group will be exhibiting three eco-friendly solutions for packaging pharmaceutical products. The decision to invest in the circular economy is part of a rapidly evolving strategic company plan, communicated in 2015 with the presentation of the first Sustainability Report, in which the Group’s environmental, social and economic/financial responsibility initiatives were presented. In advance of the 2021 Report, Marchesini Group has announced further investments in the development of new sustainable packaging materials.

At Pharmintech’s stand, A34-A44-B35-B45, the focus will be on the MA80 cartoner designed for cartoning products such as syringes, inhalers, vials and tubes at a speed of 120 cartons per minute. MA80 is designed to place products in cardboard trays as an alternative to thermoformed trays.

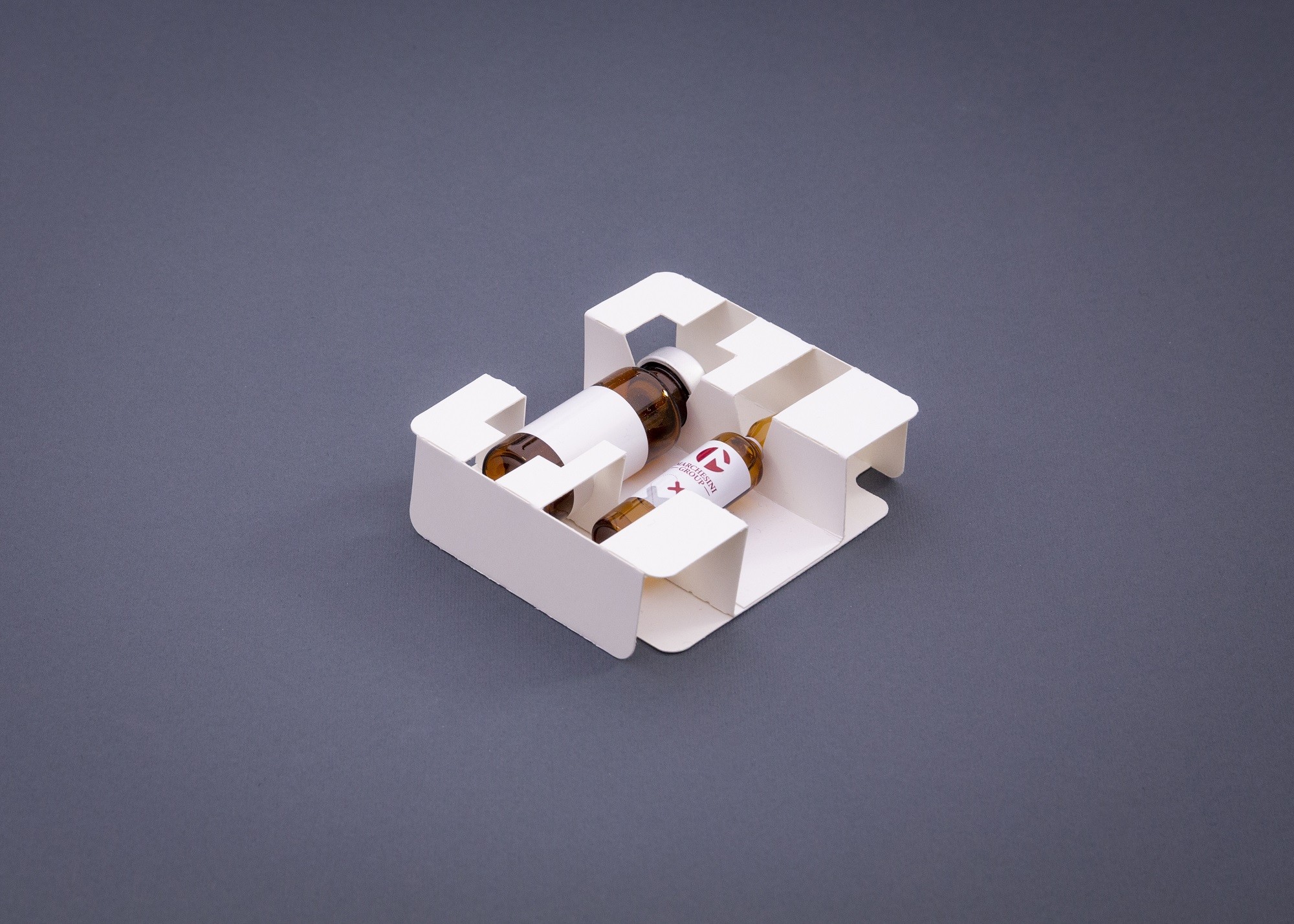

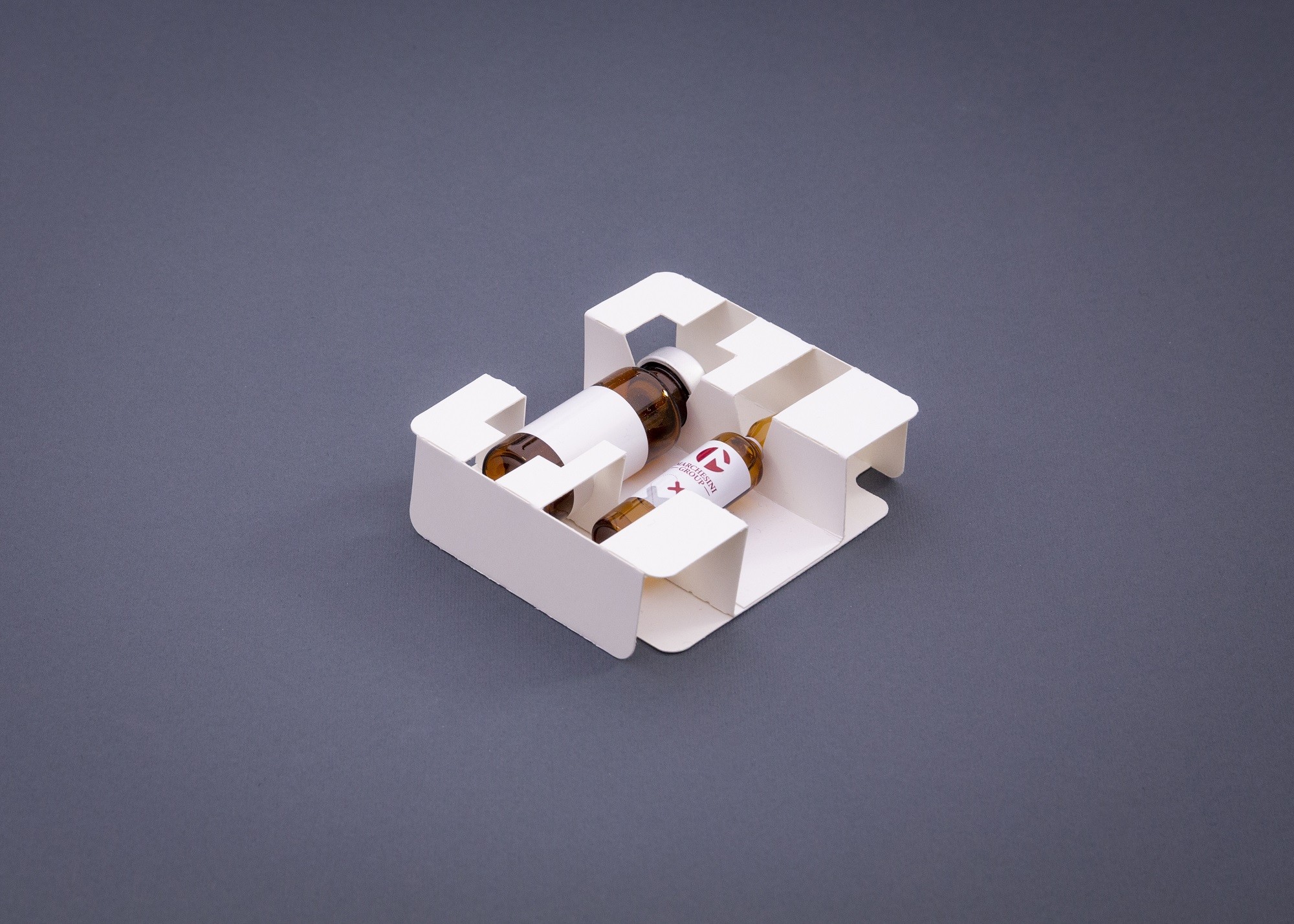

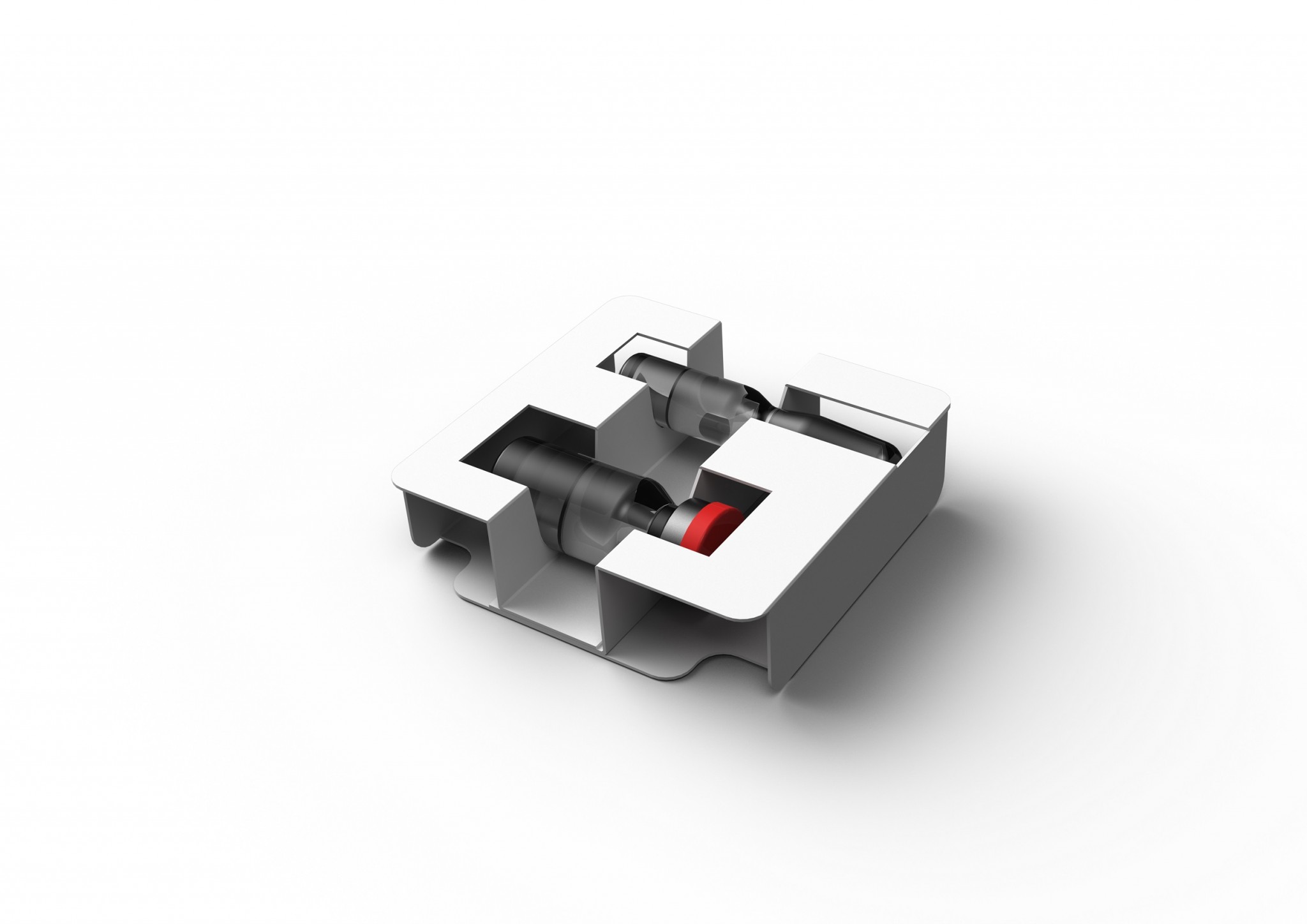

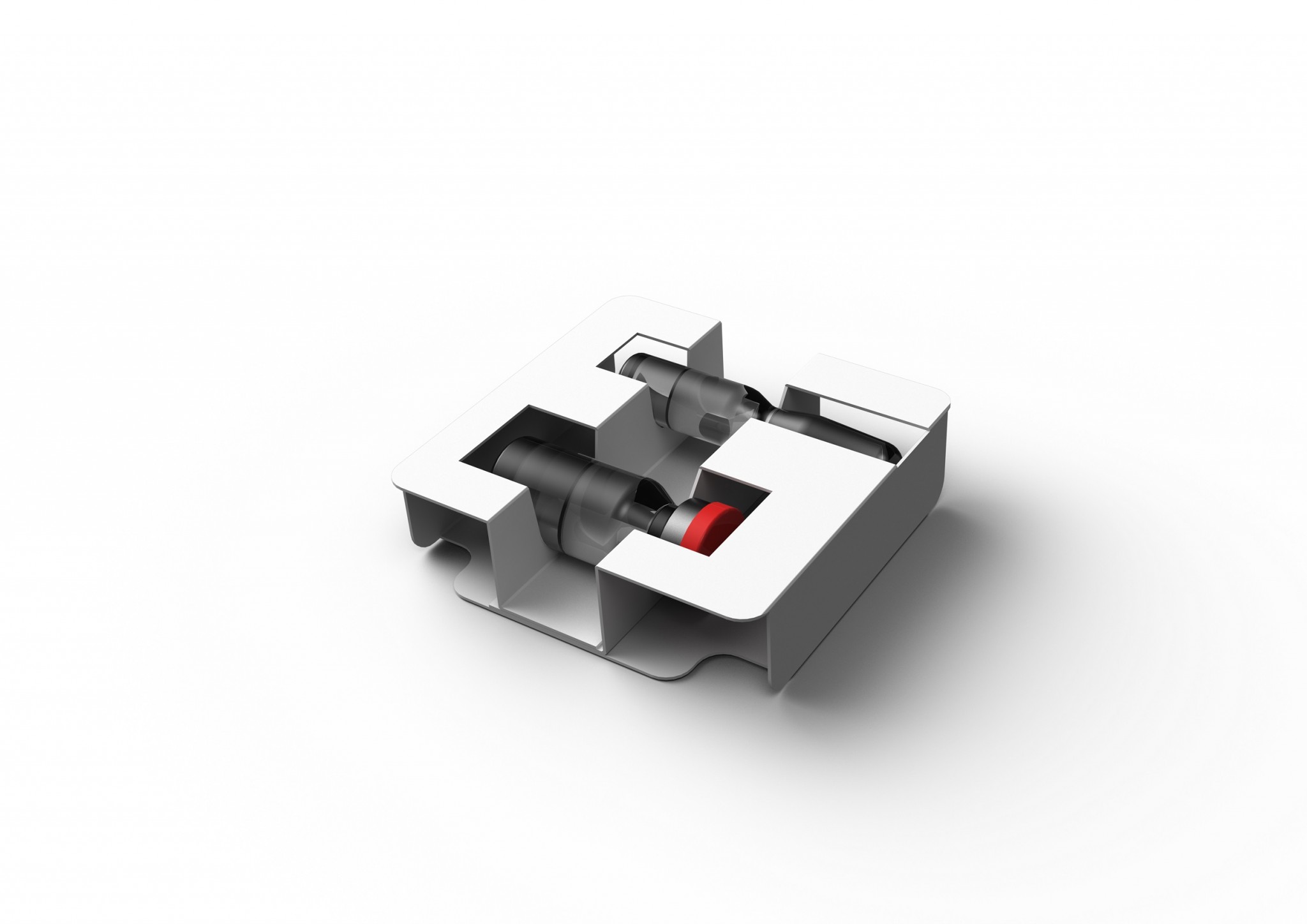

Cardboard trays are an environmentally friendly alternative that are becoming increasingly popular among customers because they are as reliable as PVC trays. They can also protect fragile and expensive products such as syringes and ampoules, presenting them in a modern, attractive way. Finally, cardboard trays offer advantages in terms of storage and transport due to their compact size.

Marchesini Group has set up a dedicated team to design customised cardboard trays for packaging products in the pharmaceutical and cosmetics market. Using prototypes and models, the trays are then fine-tuned so that customers can optimise the entire packaging line, from the process through to cartoning and palletisation.

In this process, the use of robotics is essential to create custom infeeds for handling, tray opening and subsequent product insertion. In most cases the shapes and sizes of plastics can be replicated through cardboard solutions for both standing and lying products.

Another innovation is the introduction of packaging technologies to gradually replace PVC with highly recyclable materials for thermoforming blisters and trays. In two years of experimentation and collaboration with some of the main industry players – suppliers Klöckner Pentaplast, Huhtamaki, Amcor, Paccor (Faerch Group) and Encaplast – Marchesini Group technicians have developed blisters and trays that can be easily disposed of in normal waste recycling channels. In particular, the use of plant-based and compostable materials such as PLA, which is recyclable together with the wet waste, and R-PET, PET recycled up to 80%, allowed the creation of monomaterial packs perfectly suited to the purpose.

The first public demonstration of the use of these products on a Marchesini Group machine will be at Pharmintech, where a classic FB220 – a thermoforming machine used to form trays for ampoules, vials and syringes – will be exhibited and set up to use sustainable materials instead of traditional plastics. It is up to customers to opt for either the classic or the eco-friendly approach, depending on their needs.

During Open Door Pharma, the event designed to open the company’s doors to customers from the pharmaceutical industry, the new solutions on show will be accompanied by a line consisting of a Schmucker MT1300 12-lane stick packaging machine, a stacking and counting system and an MA 80 cartoner.

Specifically, this line is designed to process PP-based packaging materials (with and without PE) such as 100% recyclable plastic monomaterials like OPP or BOPP with a metallised intermediate layer. Due to its suitability for food contact, this material is a worthy polyolefin-based substitute for the classic PET/ALU material to produce high-barrier flexible packaging.

We have recently sent a line that packages a vial and an ampoule inside a tray made of card instead of a plastic tray to an Indian customer.

The line consists of a robotic station to feed the vials and ampoules, combined with our cartoner MA300 and wrapper MF910.

We have recently sent a line that packages a vial and an ampoule inside a tray made of card instead of a plastic tray to an Indian customer.

The line consists of a robotic station to feed the vials and ampoules, combined with our cartoner MA300 and wrapper MF910.