Corporate

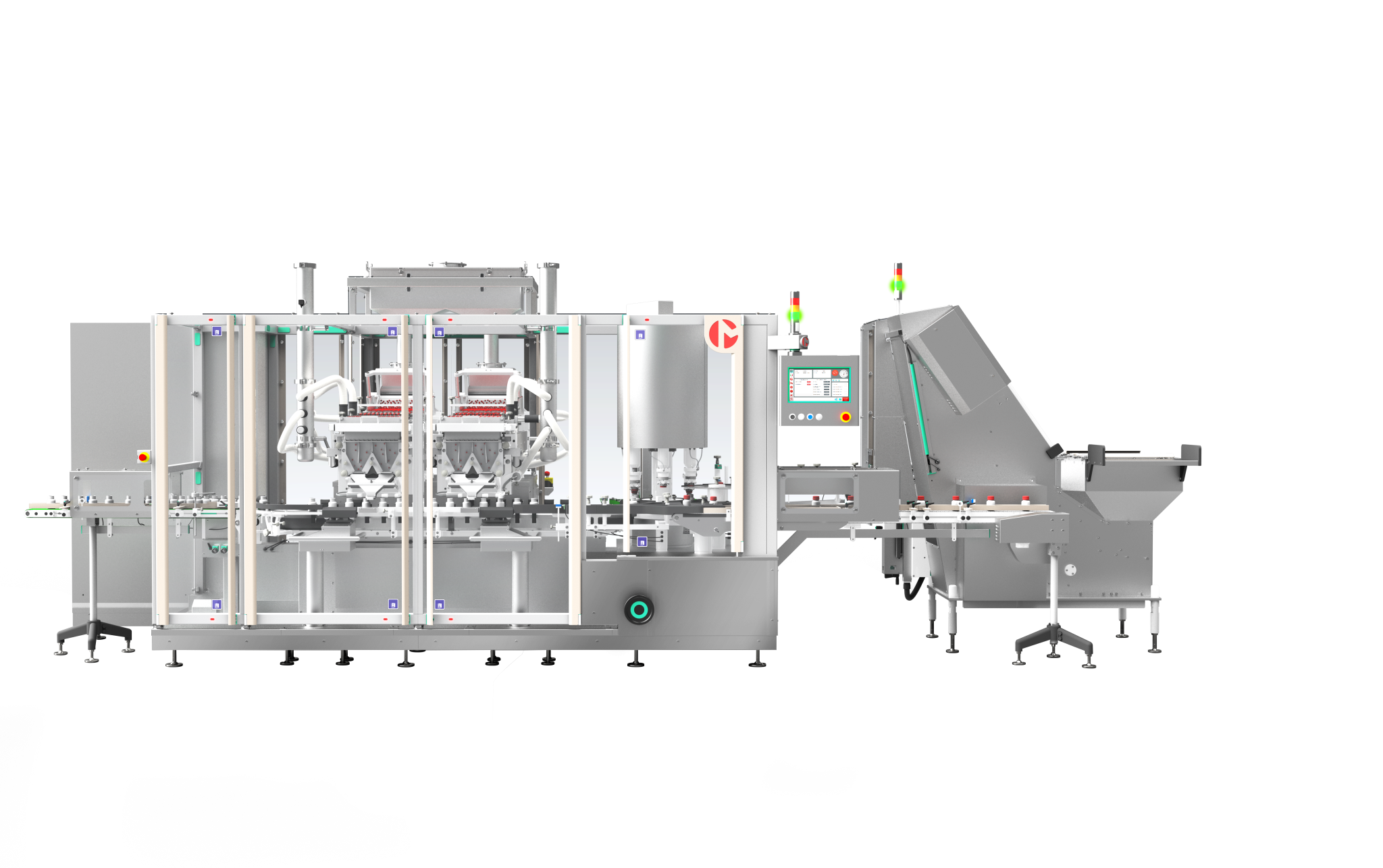

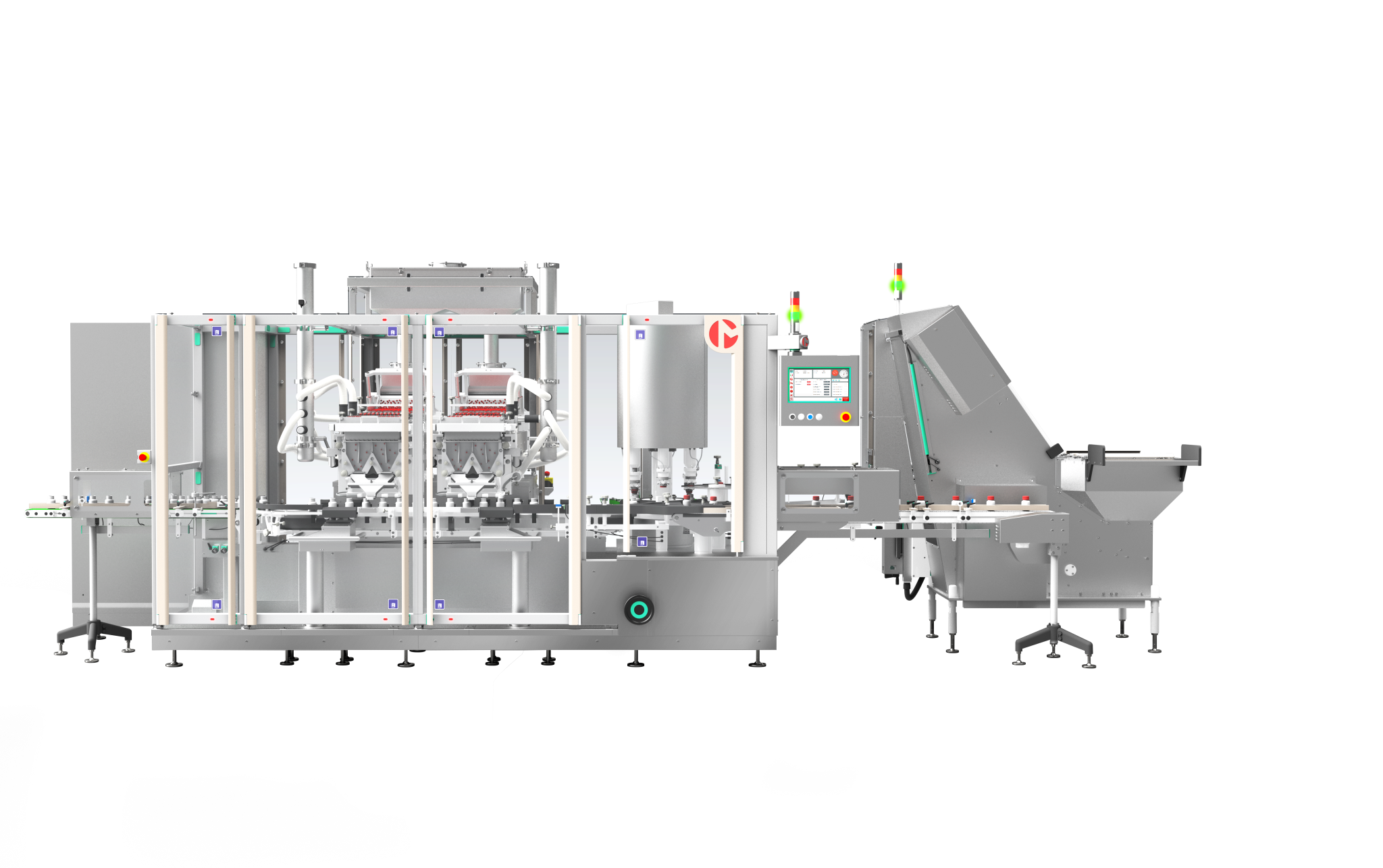

Among the innovations that Marchesini Group will present at the Open Door Pharma event, from 2 to 6 May at the Pianoro Headquarters, there will also be the Compact 24: a monobloc machine for filling and capping bottles for tablets, capsules or pills, produced by the Tonazzi-Vasquali division. This solution covers multiple operations with a single machine and ensures extremely high levels of efficiency in the crucial counting and capping stages.

What makes this monobloc so innovative is the presence of a magnetic transport system that optimizes and simplifies processes, offering very high quality and performance standards in a small space.

This solution makes it possible to overcome the limits normally associated with standard transport systems, with completely independent handling of every single bottle: positioning, bundling, and speed of movement are just some of the parameters that make this system truly one of a kind. This technology minimizes the time required to switch bottles, retrieve empty shuttles and change sizes. Moreover, the use of magnetic transport has made it possible to perfectly integrate the filling and capping stages, reducing the dimensions and simplifying the infeed of the caps.

The Compact 24 can mount all the main capping systems and offers a wide range of applications for total product control: for example, the weight can be 100% checked using the tare/gross control. In addition, at the Open Door Pharma event, costumers can see the Valida technology, which permits multivision inspection using cameras and sensors to check the shape, size and colour of tablets.

A complete check that can even assess the thickness of the tablets to detect any damage in the lower area. Finally, the Valida system permits the elimination of a single defective tablet, without impacting the product feed rate. The range is completed by technology for controlling the active ingredient, developed by our partner SEA Vision, and a vision system for complete control of the cap before it enters the machine. These solutions, in addition to pursuing the concept of "total quality", avoid unnecessary waste, ensuring greater efficiency and respect for the environment.