Corporate

Vision systems are installed directly on the production lines, perform the accurate inspection of 100% of pharmaceutical products in real-time and, thanks to an accurate signal exchange, allow the machines to reject every non-compliant product.

SEA Vision provides a complete software and hardware solution. Software uses proprietary algorithms and technologies entirely developed in-house, all the hardware parts (industrial PCs, cameras, light units, mechanical support, and others) are designed to perfectly adapt to each type of machine’s setup, guaranteeing the most stable inspection at every production speed. The vision system seamlessly integrates with machines at every automation level.

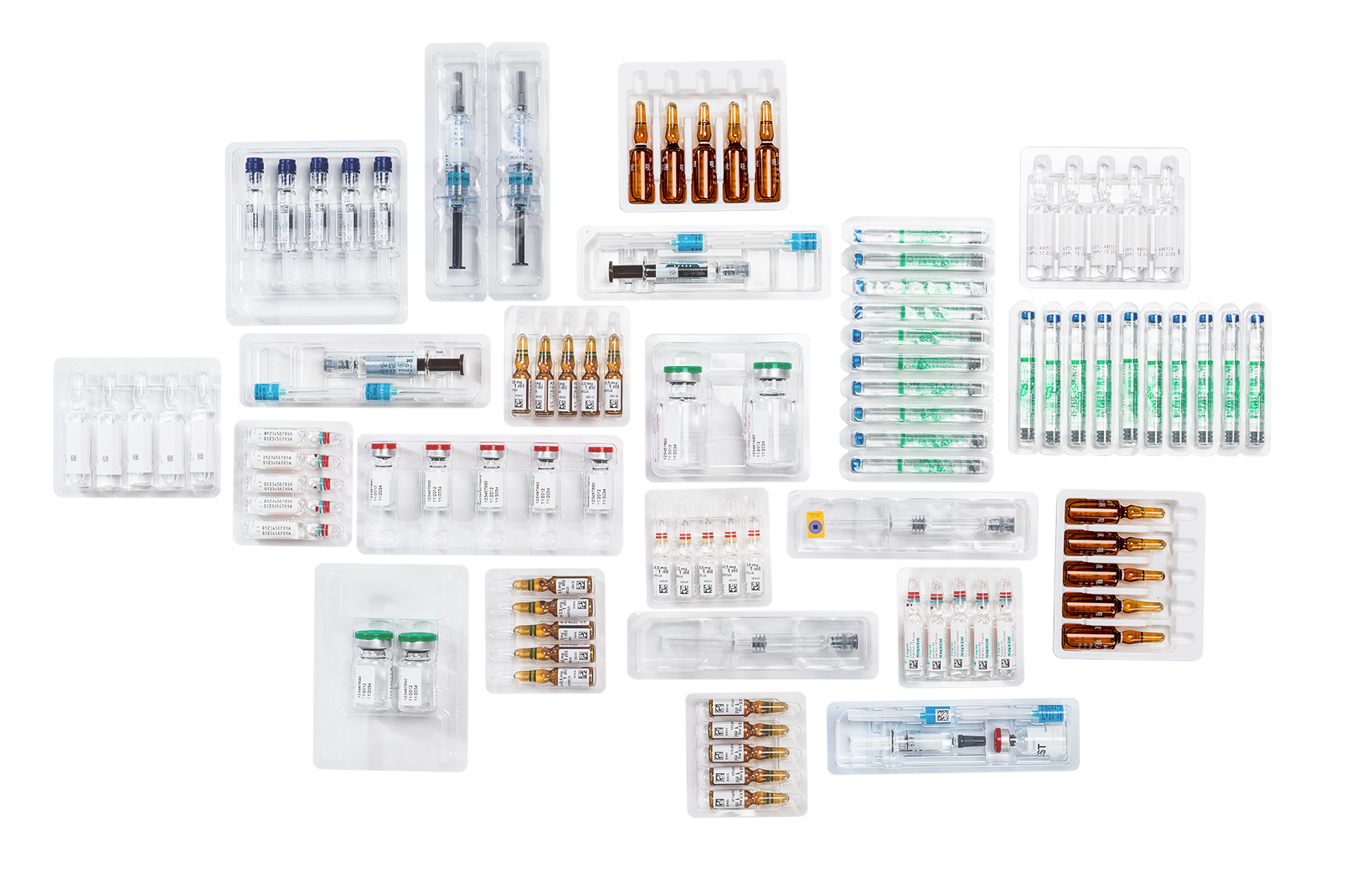

SEA Vision systems guarantee full compliance with pharmaceutical industry standards, performing inspections both during primary and secondary packaging phases.

Hardware

|

|

Software

|

Controls on oral solid products. Product size, colour, shape, integrity, and product counting.

Complete set of controls for every detail of the product and package. Tablet or capsule size, colour, shape, integrity verification. Blister completeness and correctness. Control of the integrity of the alu-alu blister (pinhole presence). Correct sealing of the sachet and strip. Control of codes, variable data, and artworks (PQV) printed on lidding foil.

Controls on stickpacks and flowpacks. Correct sealing, control of codes, variable data and artworks (PQV).

Controls on tubes and jars. Correct closure, variable data, 1D and 2D codes, correct orientation, label application, and skew.

Complete control over vials. Flip off presence and colour. Crimping control. Variable data or code on crimping. Vial integrity. Sealing membrane presence and completeness. Dropper tip presence and opening. Spray cap presence and correct crimping. Label presence and correct application.

Complete control over syringes. Plunger rod presence and colour. Correct assembly. Stopper presence. Needle shield presence. Safety device presence and correct application. Label presence and correct application.

Complete control over ampoules. Correct sealing. Colour rings correctness. Liquid presence.

Complete control on the bottlepack. Bottlepacke completeness, label presence and correct application, variable data and codes on label.

Complete control over autoinjectors. Label presence and correct application. Booklet presence, position and alignment. Dose counter number verification. Control of codes and variable data.

Complete control over inhaler actuator. Colour, integrity. Presence, integrity and colour of actuator cap. Foreign objects presence inside the actuator. Label presence and correct application. Dose counter number verification. Control of codes and variable data.

Complete control over contact lenses. Label presence and correct application. Strip completeness. Control of codes and variable data.

Complete set of controls on thermoformed or paperboard trays. Presence and correctness of components inside the tray. Correct tray forming. Variable data, codes and artwork (PQV) on lidding foil. Label presence. Product correct assembly and orientation, tray orientation.

Controls of not serialized codes and variable data on labeller, cartoner, bundling machine, overwrapping machine, case packer, case packer-palletizer. Control of printed artwork (PQV). Carton and case completeness control.

Receive the machine brochure in pdf format, directly in your e-mail inbox.